GKN Additive to mass-produce energy efficient industrial burners for Kueppers Solutions

November 22, 2019

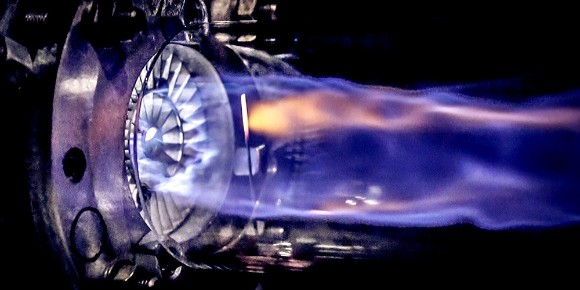

Kueppers Solutions has developed a mixing unit for natural gas burners that optimises the combustion process with a significant reduction in nitrogen oxide emissions (Courtesy Kueppers Solutions)

GKN Additive and Kueppers Solutions, a specialist for industrial combustion technology, announced at Formnext 2019 a strategic partnership that will see the mass-production of high energy-efficient mixing units for industrial burners, and tap into a new market to create a reduction of nitrogen oxide emissions in the industry.

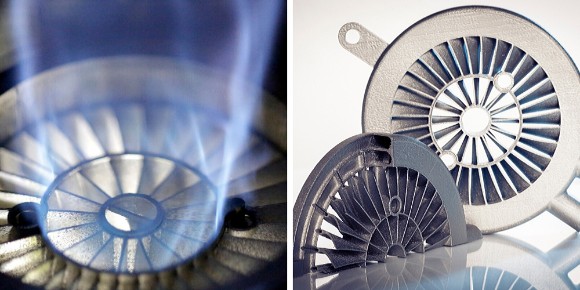

To make the burning process more efficient, Kueppers Solutions has developed a mixing unit for natural gas burners that optimises the combustion process with a significant reduction in nitrogen oxide emissions. Due to its design, the application is only feasible because of metal Additive Manufacturing.

“Together with the RWTH Aachen University, we have screened the entire market in order to find a suitable partner for the industrialisation of our product,” stated Jens te Kaat, CEO of Kueppers Solutions. “GKN Additive’s experience in series production and their application know-how across a broad range of industries is unique. Typically, we are used to explaining our project in detail to potential partners and still tend to encounter obstacles. With GKN it was the other way around: their team was the fastest to understand the potential. GKN’s ‘Let’s do it!’ mentality corresponds with our own attitude.”

Due to its intelligent design, the mixing unit is only feasible in metal Additive Manufacturing (Courtesy Kueppers Solutions)

The current focus is now on the ramp-up of the mixing unit’s series production in Selective Laser Melting (SLM) and the joint development of a unique material, engineered for the application. GKN then intends to manufacture the next generation of the mixing unit using its the HP Metal Jet, a metal binder jetting system. The application is said to be ideally suited for this process, which will result in a more cost-effective product.

“Climate change challenges all of us to think of new ways to substantially reduce emissions,” commented Guido Degen, President Additive Manufacturing at GKN Powder Metallurgy. “Kueppers’ mixing unit has made a significant contribution to preserving resources and with our experience across the whole AM value stream, we will drive the industrialisation of this highly innovative product. Our common goal is to open up the market by upgrading thousands of outdated industrial burner systems with 3D-printed mixing units.”