GKN Additive launches Titanium Beta 21S powder for metal Additive Manufacturing

November 30, 2017

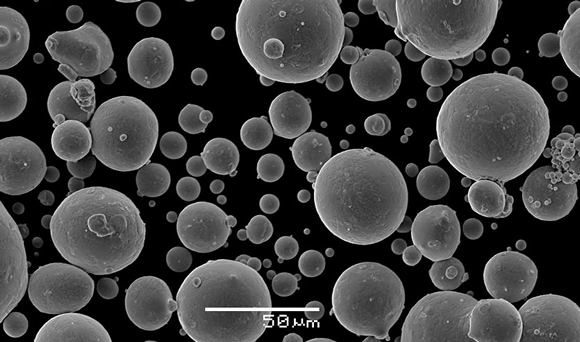

Beta 21S titanium (UNS R58210) is a high strength, heat treatable, metastable beta titanium alloy (Courtesy GKN Additive)

GKN Hoeganaes Specialty Metal Powders, the advanced materials division of GKN Additive, has added AncorTi™ Beta 21S to its portfolio of AncorAM™ powders for metal Additive Manufacturing. Beta 21S titanium (UNS R58210) is a high strength, heat treatable, metastable beta titanium alloy.

It is designed to improve resistance to oxidation and creep, as well as offering enhanced strength and stability in elevated temperatures. According to GKN Hoeganaes, these properties make the alloy a perfect candidate for the manufacturing of parts for aerospace, medical, chemical and marine applications. AncorTi Beta 21S is available in particle sizes optimised for Electron Beam Melting (EBM) and Selective Laser Melting (SLM) AM machines.

AncorAM metal powders are produced on full production scale processing equipment and engineered with alloy chemistry and powder characteristics specifically designed AM, focusing on final product consistency. AncorTi Beta 21S joins AncorTi CP and AncorTi 6Al4V, as well as a number of nickel and ferrous based powders in the AncorAM product line.

GKN Additive stated that it will continue to develop new powder alloys for AM, including advanced titanium powders, specialised nickel-based alloys, and nickel-titanium powders engineered for use in advanced medical devices.