General Motors adopts Autodesk’s newly launched generative design software for enhanced lightweighting

May 4, 2018

General Motors will use Autodesk’s generative design software to develop lightweight components for future vehicles (Courtesy Autodesk)

General Motors (GM), Detroit, Michigan, USA, has announced that it will use Autodesk’s recently-launched generative design software for Additive Manufacturing to develop lightweight components for future vehicles. Autodesk made its generative design software commercially available at the end of April, 2018, as part of its cloud-based Fusion 360 Ultimate product development tool.

GM stated that it sees Additive Manufacturing and generative design as ‘key technologies’ in the development of new products, including alternative propulsion and zero emission vehicles, and that Autodesk’s generative design software will allow the company to exceed the weight reductions made possible by traditional design optimisation techniques.

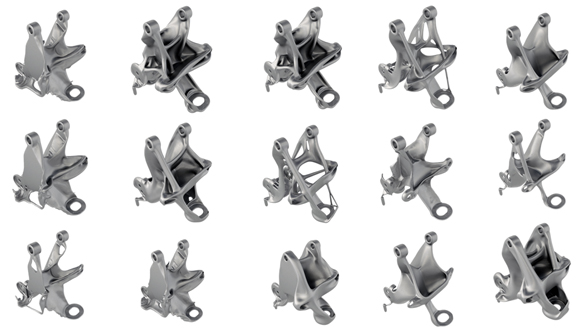

Instead of evaluating design concepts after development, generative design allows engineers to define design parameters such as material, size, weight, strength, manufacturing method and cost constraints, after which AI-based algorithms output a number of design options which meet these criteria.

Designers and engineers can then examine each option and choose the design which best meets their stated requirements. By auto-generating a number of different designs immediately, generative design software has the potential to free designers and engineers from repetitive design tasks and enable them to focus on higher-value decisions, such as maximising part performance.

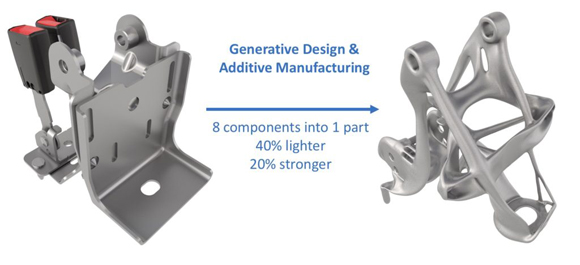

In an initial proof-of-concept project, GM and Autodesk, working from GM’s Tech Center in Warren, Michigan, reported that they used generative design to reconceive a vehicle seat bracket – the part of the seat to which seat belts are fastened.

Once the design parameters – including the required connection points, strength and mass – had been defined, Autodesk’s software produced more than 150 valid design options, enabling the team to select a new design which it believes “no human could have conceived on their own.” The new design is said to be 40% lighter and 20% stronger than the original part, and consolidates eight different components into one AM part.

Image courtesy Autodesk

General Motors has been developing its use of Additive Manufacturing for more than thirty years and reportedly holds one of the most comprehensive Additive Manufacturing equipment suites in the automotive industry. The manufacturer uses more than fifty AM systems for the rapid prototyping of parts, and has produced more than 250,000 prototypes using this method over the last decade.

“With our long-standing expertise in AM, we see incredible opportunities for generative design,” stated Kevin Quinn, GM’s Director of Additive Manufacturing. “The seat-bracket is just a small demonstration of the potential mass and strength improvements when we apply these technologies to many of the 30,000+ parts in our vehicles. Maybe even more exciting are the far-reaching transformations we can imagine as we move into an era of electric and autonomous vehicles.”

The seat bracket project is said to mark the beginning of a multi-year partnership between GM and Autodesk. Going forward, the two companies state that they will collaborate on additional projects involving generative design, Additive Manufacturing and materials science. GM will continue to use a range of Autodesk’s design software, including Fusion 360 Ultimate package for access to its generative design technology, Autodesk Netfabb for lattice optimisation and metal additive simulation, and the company’s Alias, Recap Pro and Meshmixer.

“Generative design is the future of manufacturing, and GM is a pioneer in using it to lightweight their future vehicles,” commented Scott Reese, Autodesk Senior Vice President for Manufacturing and Construction Products. “But the benefits for GM go well beyond lightweighting.”

“What really separates generative design from past technologies is the ability to consolidate many parts into one and the ability to dramatically compress the product development process. Engineers get hundreds of ready-to-manufacture design options they could never come up with manually and it happens in a fraction of the time it would take to validate a single design the old way,” he concluded.