Gefertec now wholly owned by Berlin.Industrial.Group.

February 6, 2023

Gefertec GmbH, a manufacturer of wire-based Directed Energy Deposition (DED) Additive Manufacturing machines based in Berlin, Germany, is now wholly owned by Berlin.Industrial.Group (BIG) Holding. Gefertec has been a member of BIG since its founding in 2015, with BIG now acquiring the remaining shares of Gefertec founders Tobias Röhrich and George Fischer.

“This gives GEFERTEC the necessary freedom of action to further expand and solidify its position in the growing market for 3D metal printing,” stated Igor Haschke, Managing Director, Gefertec, and owner of BIG.

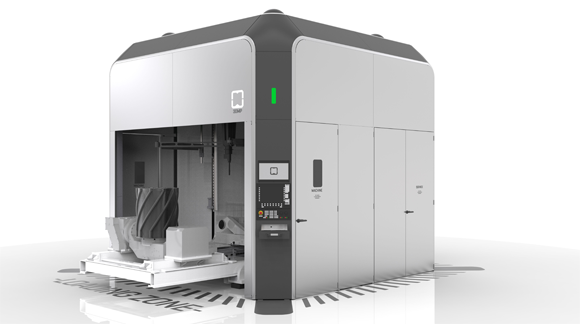

Gefertec offers a range of machines, including the arc603 with three-axis machining capable of producing metal components up to 3.0 m3 with a maximum mass of 3000 kg. The arc605 (pictured above) includes five-axis machining and is capable of producing metal components up to 0.8 m3 with a maximum mass of 500 kg.

Download Metal AM magazine