Gefertec introduces 3DMP technology with new GTarc AM machine series

December 8, 2017

The new GTarc3000-3 WAAM machine (Courtesy Gefertec)

Gefertec GmbH, Berlin, Germany, has introduced its 3DMP® manufacturing technology, a Wire Arc Additive Manufacturing (WAAM) technology which it states enables the production of parts with qualities comparable to those offered by standard manufacturing methods. The technology is offered in Gefertec’s GTarc AM machine series.

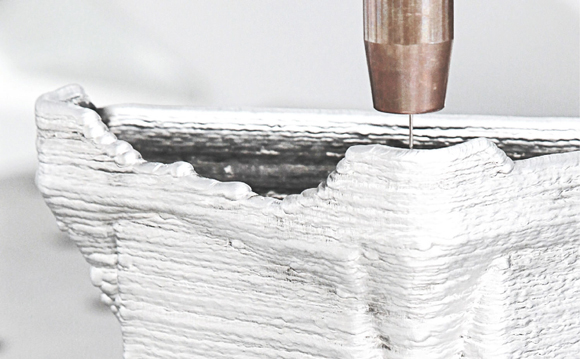

3DMP’s Wire Arc Additive Manufacturing process forms the part by welding layer on layer. According to its developers, the wire-based method offers a number of advantages compared to powder-based AM technologies, such as the elimination of powder handling and the significantly lower cost of wire compared to metal powders. In addition, WAAM is said to offer higher production speeds of up to 600cm3 per hour, depending on the material.

3DMP’s Wire Arc Additive Manufacturing process forms the part by welding layer on layer (Courtesy Gefertec)

During the recent Fabtech exhibition in Chicago, Illinois, USA, November 6-9, 2017, the company also showcased the new GTarc3000-3 WAAM machine, a 3-axis system for the production of parts up to 3 m3 with a maximum mass of 3000 kg, and GTarc800-5, a 5-axis machine for parts up to 0.8 m³ with a maximum mass of 500kg. Suitable for the production of complex, large parts made of steel, nickel, titanium or aluminium, GTarc systems are reportedly in use at FIT Group and Siemens AG.

Gefertec offers CAM software tailored to 3DMP, which draws data from each CAD-modelled part the to enable the Gtarc’s CNC-control unit to correctly position the welding head, enabling high levels of precision. Part finishing is carried out externally on a standard CNC milling machine.

Compared to other manufacturing methods, the company states that 3DMP offers maximum material utilisation, resulting in substantial cost savings of up to 60%. This could make the technology promising for applications in the aerospace industry and other applications where cost is a major factor, especially when using high-cost materials such as titanium.

The GTarc machine has a modular design intended to make future system upgrades easier. For example, customers can upgrade the 3-axis version to a 5-axis system using a pan-tilt-table.