GE to install first metal additively manufactured part on GEnx commercial airline engines

November 1, 2018

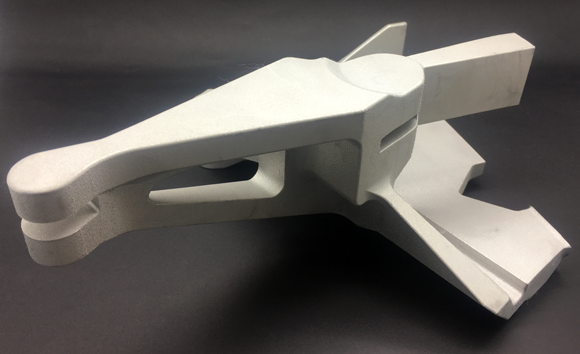

The PDOS additive bracket for GE Aviation’s GEnx-2B commercial airline engine (Courtesy GE)

The Federal Aviation Administration (FAA) has given ‘change in design’ approval to GE Additive and GE Aviation to replace a conventionally manufactured power door opening system (PDOS) bracket, used on GE Aviation’s GEnx-2B commercial airline engines, with an additively manufactured bracket.

The new additively manufactured brackets will enter mass production at GE Aviation’s facility in Auburn, Alabama, USA, using GE Additive Concept Laser M2 cusing Multilaser machines, this month. GE Aviation anticipates the first GEnx engines installed with the new brackets will be shipped in January 2019.

GEnx-2B commercial airline engines power the Boeing 747-8. The PDOS is used on the ground to open and close the fan cowl doors to enable access to the fan compartment for maintenance reasons. The original PDOS brackets on GEnx-2B engines were produced from a solid block of metal, using conventional methods such as milling; this technique resulted in around 50% of the material being wasted.

Using Laser Beam Powder Bed Fusion (LB-PBF) additive technology (referred to by GE as Direct Metal Laser Melting) to manufacture the new brackets, waste generated during the part’s manufacture has been reduced by as much as 90%. GE Aviation stated that it has also improved the design to reduce the bracket’s weight by 10%. In addition, the decision to mass produce using a cobalt-chrome alloy over a traditional nickel-based superalloy has enabled a faster build. To make this approach as efficient as possible, GE stated that four brackets will be printed at the same time.

Using a bespoke, interlocking design to house all four brackets on a single build plate, the Concept Laser M2 cusing machine’s pair of lasers can additively manufacture an aircraft’s worth of brackets in one build, before post-processing and inspection. Finally, by taking production of the brackets entirely in-house, GE Aviation also expects to reduce its production costs.

“We chose this project because it represented several firsts for us,“ stated Eric Gatlin, General Manager, Additive Integrated Product Team, GE Aviation. “It’s the first programme we certified on a Concept Laser machine. It’s also the first project we took from design to production in less than ten months.”

“To ensure the M2 cusing machines were certified to meet the strict requirements for the aerospace industry, collaboration on this programme has been closer than usual with our colleagues at GE Additive,” he added. “As we continue thinking about the many parts we can design, redesign and manufacture on GE Additive machines, I’m looking forward to putting both our teams and the technology through their paces.”

Jason Oliver, President & CEO, GE Additive, commented, “It’s been outstanding to watch teams from GE Aviation and GE Additive across the US, Mexico and Germany collaborate. In such a short space of time, they have really excelled with the PDOS bracket and achieved a truly groundbreaking success. Seeing the M2 machines produce flight quality hardware, and demonstrating what it is truly capable of, is another great milestone in our own additive journey.”