GE reports successful first test of Advanced Turboprop Engine

January 8, 2018

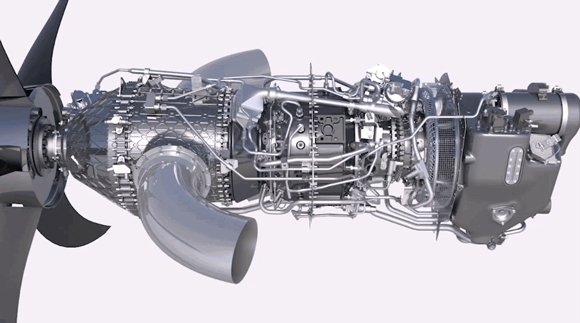

According to GE, more than a third of the ATP is metal additively manufactured from advanced alloys (Courtesy GE Reports)

GE Aviation’s Advanced Turboprop Engine (ATP) passed its first test in December 2017, reports GE. Developed over two years by approximately 400 GE designers, engineers and materials specialists in the Czech Republic, Italy, Germany, Poland and the US, this is the first civilian turboprop engine to contain metal AM components. According to GE, more than a third of the ATP is metal additively manufactured from advanced alloys.

In using metal AM, alongside other new technologies used for the first time in a civilian turboprop engine, the development team states that it was able to consolidate the number of separate components in the engine from 855 to twelve, reduce the engine weight by 100 lb, improve fuel burn by up to 20%, increase power by 10% and simplify engine maintenance. The metal additively manufactured engine components are produced at GE group company Avio Aero’s Italian plant.

This first test, which was conducted in a GE Aviation test cell in Prague, the Czech Republic, saw the ATP exposed to simulated flight conditions in a controlled testing environment. Information was then gathered about vibrations, torque, thrust and other inputs while a number of cameras monitored the engine for fuel and oil leaks.

Following the first successful test of the engine, Paul Corkery, General Manager of the Advanced Turboprop programme, stated, “This is a pivotal moment. We now have a working engine. We are moving from design and development to the next phase of the programme, ending with certification.”

GE stated that it plans to build a total of twelve ATP test vehicles, which will be tested in various specialised test cells across Europe and Canada. The company will continue to test the engine, including performance and high-vibration tests, over the next two years before it can be certified by government authorities for passenger flight. GE expects to conduct a test at altitude late in 2018.