GE Oil & Gas opens new metal Additive Manufacturing production line at Italian plant

June 17, 2016

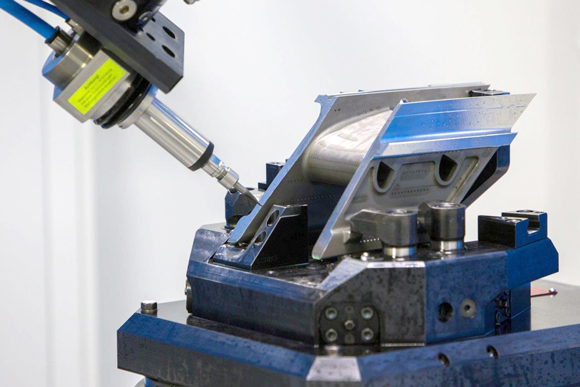

A robot automatically polishes a nozzle component in the GE Oil & Gas Talamona plant (courtesy GE Oil & Gas)

GE Oil & Gas has announced a new metal Additive Manufacturing line has been established to produce high-tech end burners for gas turbine combustion chambers at its plant in Talamona, Italy. The company also announced that a completely automated production line, incorporating advanced anthropomorphic robots, has been established for the manufacture of nozzles at the facility.

After extensive validation of Additive Manufacturing during prototyping of the NovaLT16 gas turbine, GE stated that it decided to move the technology into full production, leveraging the design enhancement capabilities, cycle time reduction and improved product quality.

“The use of automated production and new techniques like Additive Manufacturing allow us to develop parts and products more efficiently, precisely and cost-effectively, accelerating the speed at which we can bring product to market,” stated Davide Marrani, General Manager Manufacturing for business Turbomachinery Solutions at GE Oil & Gas.

The official unveiling of the upgraded turbine and compressor components manufacturing facility is the result of some €10 million investment over two years. The new production lines are already working and will be fully operational by the start of 2017.

“Our investment in these technologies at this site reflects our ongoing commitment to combine cutting edge technology and new manufacturing processes to lower cost and accelerate the innovation, speed and performance of industrial products,” added Marrani.

GE has been investing and growing its work in Additive Manufacturing across R&D sites spanning Bangalore (India), Niskayuna (Japan), Michigan (United States), Shanghai (China) and Munich (Germany). The applications for that work span the entire GE footprint, including the use of cobalt-chromium alloys for jet engines that were originally used for joint replacements and dental implants. Talamona coming online brings years of automation and 3D printing development and investment to fruition, the company stated.

GE Oil & Gas opened an additive lab in Florence, Italy, in 2013 with the installation of its first Direct Metal Laser Melting machine. Since then, the laboratory has grown its capabilities thanks to the addition of two further machines for the development of Turbomachinery components and special alloys. Collaborations with GE Aviation and GE Global Research Centre have significantly accelerated the development of the technology within GE.

“The opportunities for the application of Additive Manufacturing and 3D printing in the oil and gas industry are only just starting to be explored, and it will require an ongoing rethink of component design and production approach,” stated Massimiliano Cecconi, GE Oil & Gas Materials & Manufacturing Technologies Executive. “GE Oil & Gas is fostering the development of this technology to produce complex components for gas turbines, while cutting costs, boosting performance and reducing emissions.”