GE Additive unveils Arcam EBM Spectra H

April 25, 2018

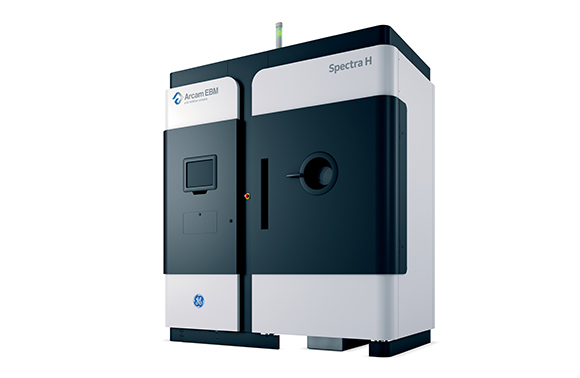

Arcam EBM Spectra H system. (Photo: GE Additive)

This week GE Additive unveiled the Arcam EBM Spectra™ H, a new metal Additive Manufacturing system designed to handle high heat and crack-prone materials. The Arcam EBM Spectra H complements the company’s existing Electron Beam Melting (EBM) systems.

Unveiled at the RAPID + TCT 2018 show, Fort Worth, Texas, USA, the new system is now available to pre-order. It will be manufactured at Arcam’s plant near Gothenburg, Sweden, with expected delivery from Q4 2018 onwards.

GE Additive states that as manufacturers make significant steps towards serial production, they require larger, faster, industrialised solutions and machines that are capable of handling high heat and crack-prone materials, such as titanium aluminide (TiAl). Today, EBM systems remain the only commercial Additive Manufacturing method able to support TiAl production requirements.

Initially, the Arcam EBM Spectra H will support both TiAl and Alloy 718 and additional Ni superalloys will be supported from 2019. GE Additive’s materials science team is currently exploring future opportunities for a wider range of high heat materials that includes nickel superalloys, tungsten, CoCr, stainless steel and metal matrix composites.

Reducing costs through increased productivity

The Arcam EBM Spectra H incorporates a range of new features and enhancements to drive down cost by increasing system productivity. An increased build speed of up to 50% has been achieved through the use of a 6kW HV-unit, resulting in all pre- and post-heating steps taking half the time of current EBM machines

Improved heat management has also been achieved through the incorporation of a moveable heat shield to keep heat in the build area, and an improved layering procedure reduces the need for heating, saving approximately five hours for a full height build.

The Spectra H’s build volume has also been increased by 39% compared to previous generation machines, increasing from 200 x 200 x 380 mm to Ø250 x 430 mm.

Further machine enhancements include Arcam xQam™ automatic calibration technology, which, it is claimed, improves the position and focus accuracy and removes the need for manual calibration, reducing the process from three to four hours to fifteen minutes. This innovation will also be incorporated on the Arcam EBM Spectra H and all Qplus systems.

A focus on end-to-end industrialisation

GE Additive stated that reducing dependency on operators and incorporating automation technologies to improve accuracy was a major focus during the development of the new machine.

As a result, the system offers a significantly improved and automated power handling process. An automated, self-dosing sieve and hopper filling station process has been developed and powder weight is controlled in the Powder Recovery Station (PRS) and inside the hopper filling station.

Machine set-up has been simplified through the use of automatic powder hoppers, which are self-closing when lifted and self-opening when mounted in the machine. Only one powder distribution set-up is required for each material and calibration of the fetch position only needs to take place during a material change, no longer before machine start.

Enhanced safety features

Advanced safety features have also been incorporated into the new machine, including closed powder handling, which also maintains batch integrity and reduces the risk of contamination.

As well as protecting the operator from the powder, the dust tight environment in all steps of the process maintains powder batch integrity. Removal of unwanted particles is handled by a thorough process that includes a cyclone for small and low-density particles, a sieve for coarse particles and magnetic traps.

“This new system shows our commitment to developing industry-leading additive machines, materials and services. We remain focused on accelerating innovation across sectors and helping the world work smarter, faster and more efficiently,” said Jason Oliver, President and CEO, GE Additive.

“It’s great to be able to show the Spectra H here at RAPID and get feedback from across the industry. We have created what we think is an amazing system that demonstrates how Arcam continues to push the possibilities of EBM technology. Spectra H is the result of really hard work by a cross-functional team from across the GE Additive family, supported by insights and feedback from a handful of internal and external customers,” said Karl Lindblom, General Manager, Arcam EBM.