GE Additive introduces Amp software platform

November 19, 2021

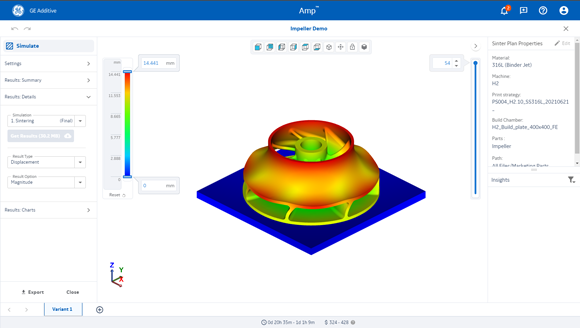

At Formnext 2021, GE Additive debuted its Amp process management software platform. The company also announced limited release, from mid-November, of the first two modules: Print Model and Simulation & Compensation, for Concept Laser M2 machines. Wider release is planned for the second quarter of 2022.

“Our vision is simple: we want to make it as easy as possible for our customers to develop and 3D print parts quickly and efficiently,” stated Igal Kaptsan, General Manager – Software, GE Additive. “That way, they can get to production and industrialisation faster. Amp is the fourth pillar in GE Additive’s full solution along with machines, materials and services.”

Amp leverages the knowledge of GE Additive, GE Aviation and GE Global Research and takes best practices and know-how from their applications, incorporating them directly into the integrated software solution. The company anticipates that users will now be enabled to make moves quicker toward industrialisation with a consistent and streamlined process.

“At GE, we are in an enviable position of being both the largest user of metal additive technology, as well as being a manufacturer of machines and powders, so we understand first-hand the challenges other users face when industrialising metal additive. And when we couldn’t find a software solution that met our needs and was easy to use, we created one. As we developed Amp, my team has benefited from close collaboration with teams at GE Aviation and at GE Global Research – actual additive users working on an industrial scale – to get their perspective and invaluable feedback,” added Kaptsan.

Developed and designed exclusively for GE Additive machine customers, Amp integrates tools to manage, process and manufacture metal AM parts from development to production on a single integrated platform. The software is anticipated to improve part production and significantly reduce the trial & error needed to develop build-ready parts.

Amp breaks down the silos between CAD, build prep, simulation, compensation and inspection data to in an effort to improve part production. Using centralised data, tools simulate how the manufacturing process unfolds in real time and estimates cost and time for a part throughout the process. In addition to the database, the software also incorporates the industrial knowledge, best practices and workflows, and time/cost analyses that GE has pioneered over the past decade.

Calculations for these tasks depend heavily on the material and the AM machines being used. To produce accurate simulations, users must enter information about the build, ranging from laser power and speed to powder size and distribution. Amp aims to solve this problem by closely tying Amp to GE Additive’s own PBF-LB machines, starting with the Concept Laser M2. The M Line and Binder Jet (BJT) solutions and eventually other laser and Electron Beam Powder Bed Fusion (PBF-EB) machines will follow.

By combining this with knowledge of material properties, Amp offers ‘recipes’ that have been pre-populated with all the parameters they need to additively manufacture parts. The software is expected to enable engineers to move through design and development faster, helping them solve big problems, take on larger parts and make it easier to apply AM to a broader range of parts.

Benefits of the Print Model are said to include:

- The automation of manual tasks based on real-world best practices

- Cloud-based architecture allow tasks to be completed in the background

- Tracks the relationships captured between various inputs and provides history of built parts

- Leverages CAD models

- Captures known fail points and notifies of potential failure points before build

Typical 1:1 compensation methods may lack precision and result in too much trial & error. Traditional simulation tools require many input variables that additive engineers might not have access to, which can make the process overly complex. Using lessons learned after years of AM development, GE Additive aimed to streamline the simulation experience to help support experienced and new users with recommendations based on best practices.

Amp’s Simulation and Compensation module adds predictive capability to builds by anticipating distortions, residual stresses, recoater interference and defects prior to manufacturing and applying corrections before launching production in an effort to reduce the trial & error process.

Benefits of the Simulation & Compensation Module are said to include:

- Easily add simulation to the additive process

- A smooth flow in one environment from Build Preparation to Simulation & Compensation, with all interactions are saved for future needs

- Users are able to digitally iterate until their design intent is achieved, reducing trial builds

- Reduces costs associated with material and manpower

Both the Print Model and Simulation & Compensation modules will be available as a limited release from November 23, 2021. GE Additive is inviting Concept Laser M2 customers to sign up for a free six-month trial period to test the Amp platform in a production environment.

Jeremy Harrington, VP – Business Development, Software at GE Additive, concluded, “We know from our work on binder jet and M Line that this iterative, customer-centric approach works really well and helps us continuously improve Amp as we prepare for wider release in Q2 next year.”