Freemelt’s Pixelmelt enables increased freedom for process optimisation

May 17, 2022

Freemelt, Mölndal, Sweden, has introduced Pixelmelt, a new software solution designed for faster material development and more productive Additive Manufacturing. Available in the third quarter of 2022, Pixelmelt is said to offer the user increased freedom in terms of process optimisation, enabling process parameters to be varied between different components in the same build, and also within each individual component.

By using an electron beam rather than a laser beam, Freemelt’s Electron Beam Powder Bed Fusion (PBF-EB) machines offer several inherent advantages, most notably that materials can be melted at higher power and the beam can move faster. This allows the development of processes that are not possible in laser systems.

“A laser-based 3D printer can scan the beam at around 10 meters per second. Freemelt’s proprietary electron beam can move the beam 4,000 meters per second, several hundred times faster than a laser beam. This means that the beam can jump between tens of thousands of melting points every second and distribute the heat in an optimal way,” stated Ulric Ljungblad, CEO of Freemelt.

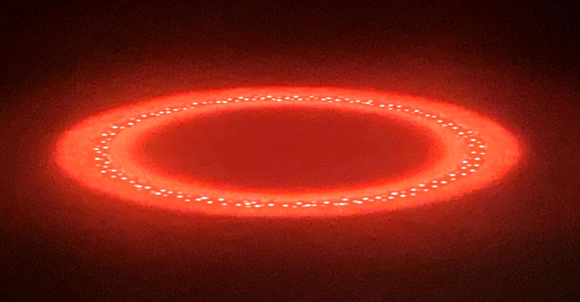

“With Pixelmelt, our customers can now melt powder material in free spot patterns over a surface rather than along parallel lines, increasing their productivity and enabling new material innovations,” added Ljungblad.

Philip Nilsson, project manager for Pixelmelt continued, “In a first step, Pixelmelt will be used for the Freemelt ONE research system to make the company’s research customers even more innovative and productive. Pixelmelt will initially be a new universal tool in the customer’s toolbox to be transferred to future industrial systems.”