Fraunhofer IWS and partners additively manufacture pure copper components for linear accelerators

November 10, 2021

Researchers from the Fraunhofer Institute for Material and Beam Technology IWS (Fraunhofer IWS), together with the European Organisation for Nuclear Research (CERN) in Switzerland, Latvia’s Riga Technology University, and Politecnico di Milano, Italy, are reported to have additively manufactured pure copper quadrupole components, essential for use in linear particle accelerators.

Used in cancer therapy, drug detection and material analysis, a new generation of particle accelerators are compact and becoming more affordable, even for smaller hospitals, airports and laboratories.

As part of the I.FAST project, aimed at enhancing innovation in accelerators and co-funded by the European Commission’s Horizon 2020 programme, the high-frequency quadrupoles are based on a new technology developed at CERN. The scientists see great potential in using pure copper Additive Manufacturing, allowing a significant reduction in manufacturing time as well as savings in material consumption when compared to traditional processes.

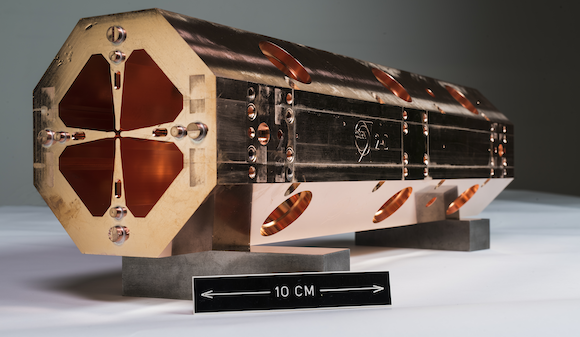

The technology opens up new opportunities for commercial production and practical use of such systems, operating on the principle of high frequency radio frequency quadrupoles (HF-RFQ). In the quadrupoles, four alternately poled electrodes face one another to form a petal-like pattern around a central particle trajectory. If the user applies an alternating voltage, rapidly changing electric fields will build up. These fields send the particles between the wavy electrode tips on a wave ride that brings them closer and closer to the speed of light with each passing electrode ‘petal’. Unlike the relatively huge underground systems, called ring accelerators, these linear accelerators often take up little more space than a typical living room.

Previously, the production of quadrupoles was very complex: they were milled into shape from semi-finished products and then assembled from a very large number of individual parts.

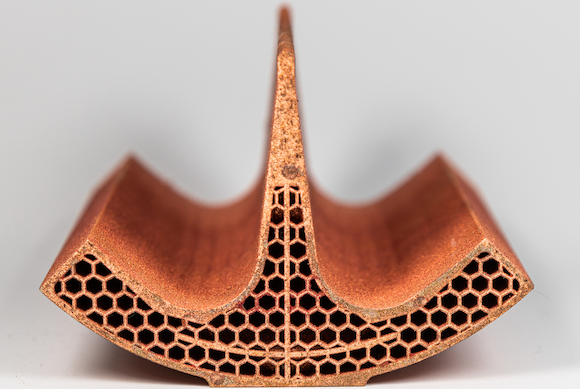

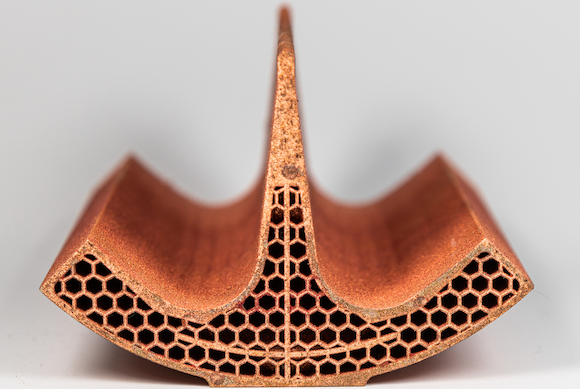

This new research has enabled the production of quarter segments of the quadrupole from pure copper powder using Laser Beam Powder Bed Fusion (PBF-LB). Using this Additive Manufacturing technology, copper consumption is reduced and the resultant quadrupole segments are lighter and can be assembled within a single day. An increase in the build volume of PBF-LB machines is expected to enable entire quadrupole segments to be produced by AM.

The quarter segments currently produced are already capable of supporting the next project phases. One such project is the determination of which smoothing technology is preferable for these quadrupoles: plasma, electrochemical or laser polishing. The project agenda also includes tests to determine whether (and, if so how) minor wear damage on accelerators can be repaired using AM without having to scrap entire components and what other accelerator materials or components are suitable for AM.

Linear accelerators are not only of interest for particle physicists and this most recent success opens up new prospects for commercial production and practical use of such systems, operating on the principle of high-frequency radio frequency quadrupoles (HF-RFQ). These systems could be used, for example, for better and more automated drug and weapons checks at airports. In the field of medical applications, they can be used for proton therapy against tumours in the abdomen or brain, as well as for medical isotope production. CERN is exploring other applications for the quadrupole accelerators, including material analysis with the purpose of examining art masterpieces.

Further information on the research is available in the paper ‘First Proof-of-Concept Prototype of an Additive-Manufactured Radio Frequency Quadrupole‘.