Fraunhofer ILT contributes to project for AI-integrated AM railway parts

November 4, 2021

Researchers from the Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, have recently been working with ME-Messsysteme GmbH, vedisys AG, and DATAbility GmbH to develop maintenance and repair solutions at DB Systemtechnik GmbH, Europe’s largest competence centre for railway technology. As part of the SenseTrAIn project, funded by the Federal Ministry for Economic Affairs and Energy BMWi, researchers aim to develop a simple, cost-effective AI-supported sensor system capable of efficiently monitoring safety functions for rail transport by 2024.

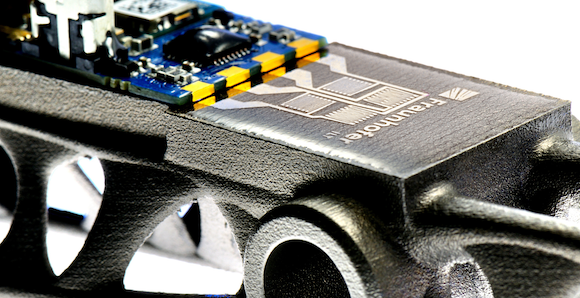

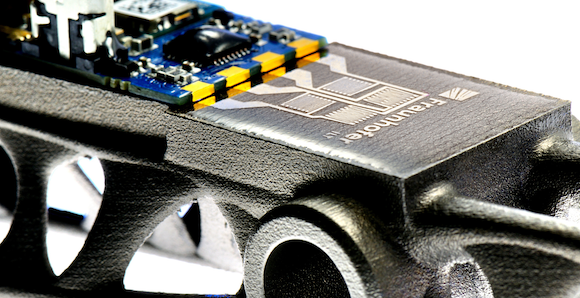

The SenseTrAIn project utilises Laser Beam Powder Bed Fusion (PBF-LB) to integrate electronic components (e.g., sensors and actuators) into metallic components. By pausing the build process at the right time, sensors can be integrated into the additively manufactured component before its completion. Networked and controlled by AI, the finished system is intended to signal whether, when and where a replacement or repair is necessary – as such, there is the necessity for wireless data transmission. This is expected to be implemented with the help of 5G technology.

The project partners also identified possible applications using technology scouting; promising fields include door mechanisms, primary & yaw dampers and, above all, wheelset bearing caps, which seal off wheel bearing housings. The latter is a critical component from a maintenance perspective: here, under increased load, the temperature rises and there is a great risk of wear. Temperature and acceleration sensors integrated into the cover could detect hot runners themselves as well as the causes at an early stage. The use of AI in combination with the sensors makes detection and further processing possible in the first place.

But no AI works well without a database. While, ideally, it should be generated directly on the systems controlled, researchers at Fraunhofer ILT have stated the impossibility of this. Instead, extensive testing under realistic conditions is being carried out in the TrainLab of the Deutsche Bahn Technik. The data obtained through this lab testing phase will be used to train the AI before the system is tested in everyday operation.

Fraunhofer ILT intends to showcase a practical demonstrator of this sensor-integrated AM technology at Formnext 2021.