Fraunhofer develops large scale SLM system

November 9, 2017

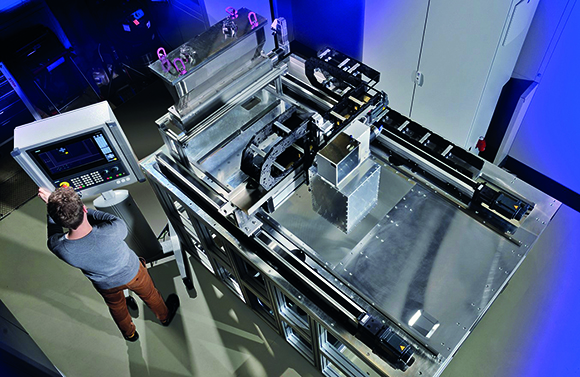

With a laboratory system, Fraunhofer ILT is further developing SLM into a 3D printing technology for large metal components. (machine housing not shown) © Fraunhofer ILT, Aachen, Germany

Fraunhofer Institute for Laser Technology (ILT), Aachen, Germany, has announced the development of a new, large scale SLM laboratory system with a usable build volume of 1,000 mm x 800 mm x 500 mm. The new Additive Manufacturing system highlights the institutes work on innovative strategies for exposure and shielding gas flow, allowing the manufacture of large metal components quickly and with high process reliability.

It is stated that established inert gas suction strategies are no longer effective for a very large build volume. Scientists at Fraunhofer ILT are therefore basing their approach on small, movable processing heads with a local shielding system, which ensures a constant stream of inert gas at every processing point for build volumes of any size.

Researches are reported to be testing systems with fiber lasers as well as exposure concepts with cost-effective diode lasers. In addition to research into established scanner systems with mirrors, they are also investigating a moving processing head with highly dynamic linear axes and several individually controllable diode lasers.

The advantage of this multi-spot processing is the ability to significantly and cost-effectively increase the system’s build-up rate by increasing the number of beam sources. The new system concept reportedly makes it possible to increase the build volume solely by extending the travel length of the axis system, without changing the optical system.

The research findings are said to give machine manufacturers a foundation upon which to develop and build the next generation of SLM systems. “We hope that the system concept will lead to a breakthrough in the successful use of this technology in series manufacturing,” stated Christian Tenbrock, scientist in the Rapid Manufacturing group. “We create process conditions that are constant and easy to control, thereby improving process robustness.”

Fraunhofer ILT at formnext

Using process videos, the ILT scientists will be demonstrating how the new laboratory system is able to swiftly manufacture large components with high process reliability at the joint Fraunhofer booth F50 in Hall 3.0 at the formnext trade fair from November 14 to 17, 2017 in Frankfurt.