Flow distributor and mixer designs optimised through metal Additive Manufacturing

January 23, 2020

Researchers at Australia’s RMIT University, Melbourne, and the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Clayton, have utilised metal Additive Manufacturing to develop flow distributor and mixer designs which enable the uniform distribution and mixing of fluids, a common functional requirement in a range of fluid handling applications.

Such flow distributors are needed in a number of industries, for fuel burners, heat exchangers, spray manifolds, bubble columns and spargers, and catalytic converters. In many applications, system performance is directly dependent on the uniformity of flow distribution.

For example, in chemical reactors utilising catalytically coated monoliths comprising many parallel channels, variation in the flow distribution across channels results in non-uniformity of catalyst utilisation. Similarly, in large-area gas burners, maldistribution of fuel and oxidisers and non-uniform mixing can result in uneven temperature distribution and combustion inefficiencies.

A range of flow distributor designs have been used in practice; however, the ability of common flow distributors to achieve high flow uniformity over many outlet channels and flow conditions has been limited, often by design compromises required to satisfy traditional manufacturing process constraints for machining or casting.

Applications requiring uniform flow distribution and fluid mixing further complicate the required geometry and limits conventional manufacturing processes. However, according to the research team, the maturing of metal Additive Manufacturing processes, such as Laser Powder Bed Fusion (L-PBF), has significantly increased the range of manufacturable geometries, enabling the construction of high-performance flow distribution devices which were not previously feasible.

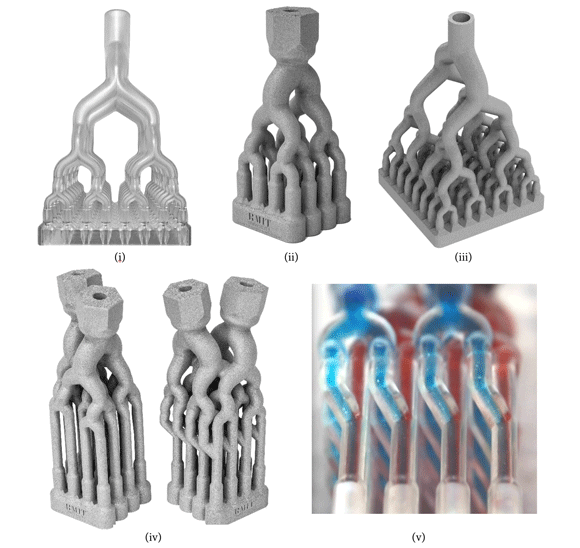

To exploit this opportunity, the researchers have developed flow distributor and mixer designs based on a recursively self-similar flow bifurcation scheme, which achieves very high outlet flow uniformity and packing density.

Inspired by recursive bifurcation flow distribution systems encountered in nature, such as in plants, blood vessels, and lung bronchial trees, the researchers observed that such systems achieve good performance due to generally symmetric and repeating flow paths. By using a similar symmetric approach tailored for Additive Manufacturing, the RMIT design is said to achieve high flow uniformity across a broad range of channel diameters, number of outlet channels, and flow conditions.

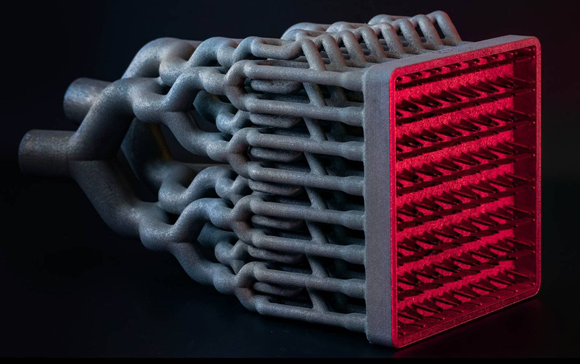

By integrating design for Additive Manufacturing considerations, the flow distributor designs can be manufactured efficiently due to the use of an inherently self-supporting geometry. The example 16 x 16 channel outlet flow distributor and mixer shown above is entirely self-supporting, with no support structures required for manufacture and complete internal void powder recovery resulting in very high manufacturing efficiency.

A range of devices have been manufactured by L-PBF from titanium and nickel alloys, with varying design configurations. Experimental testing is said to confirm the predicted high flow uniformity, and the resulting patented flow distribution system has the potential to improve performance across many industrial applications, particularly in chemical process intensification applications such as milli/microchannel reactors, contactors, and static mixers.

The team’s research was published in Science Direct, Volume 143. For further information, contact Dr Maciej Mazur ([email protected]).