Farsoon Europe strengthens team as part of Additive Manufacturing growth plan

February 6, 2024

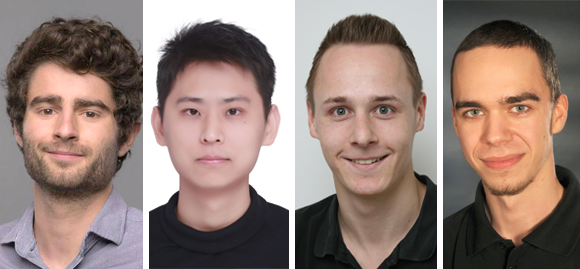

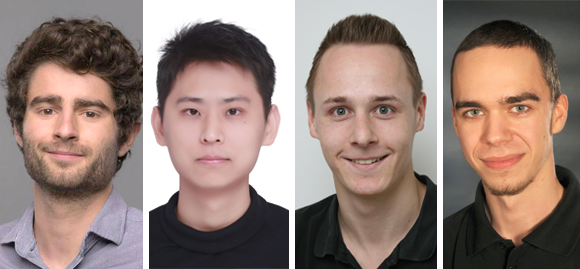

Farsoon Europe GmbH, based in Stuttgart, Germany, the European subsidiary of Additive Manufacturing machine maker Farsoon Technology Inc., headquartered in Changsha, China, has announced the addition of four new members to its team. The new hires, Kevin Veysseix, Simon Song, René Kopatsch and Louis Rankel, join the company as part of Farsoon’s strategic growth plan as it looks to further strengthen its position in the region.

Farsoon announced that it has appointed Kevin Veysseix as Territory Technical Support Manager. “Bringing over seven years in Additive Manufacturing, I look forward to combining my technical experience and customer focus to this newly created Territory Technical Support Manager role,” stated Veysseix. “Farsoon is the leading player in the AM industry and I’m eager to continue pushing users to scale Additive Manufacturing to real production.”

Following a move from the company’s China-based operations, Simon Song has joined Farsoon Europe as a Technical Service Engineer. “Transitioning from Farsoon China to Farsoon Europe has provided me with a broader perspective on the Additive Manufacturing industry, allowing for closer observation of market trends and a deeper understanding of AM technologies,” added Song. “This transition empowers me to stay updated on the latest industry trends, technological advancements, and best practices. With this commitment, I am well-prepared as a forward-thinking professional to contribute to Farsoon Europe’s mission of advancing Additive Manufacturing across the continent.”

René Kopatsch has also joined the company as a Technical Service Engineer. “I have been in the Additive Manufacturing industry for five years, first as a working student and for four years as a process engineer responsible for parameter development and validation of new components,” he stated. “Farsoon is a good opportunity for me to gain deeper knowledge about polymer printers, the tasks in the service area and the interaction with customers, but also to join a company with enormous growth potential, which has already proven this several times in recent years.”

Having worked in the AM industry for the last six years, Farsoon also appointed Louis Rankel as a Technical Service Engineer. “Since 2015, Additive Manufacturing has been my greatest passion, both professionally and personally. With nine years of field service experience, six of which have been in the AM industry, I’m confident in my ability to provide outstanding service to an ever-growing customer base. I’m honoured to join a team of highly dedicated professionals with a fresh and innovative outlook on the industry in which I feel at home. As a member of the Farsoon team, I have a great opportunity to develop my skills and knowledge, collaborate and build successful relationships with colleagues and clients who are as passionate about this technology as I am,” Rankel concluded.

Download Metal AM magazine