Farsoon and Next Chapter Manufacturing develop H13 components with conformal cooling

September 1, 2019

Farsoon Technologies, headquartered in Hunan, China, has collaborated with its partner Next Chapter Manufacturing (NXCMFG), Grand Rapids, Michigan, USA, to develop advanced process parameters for the production of robust H13 tool steel components using Laser Powder Bed Fusion (L-PBF) Additive Manufacturing. H13 tool steel is used for more hot work tooling applications than other grades of tool steel, as well as in a variety of cold work conditions, because of its high toughness and good stability.

H13 is suited to a range of applications, from die casting, extrusion dies and highly tough and polished (up to A1 grade) injection moulding components. However, its high carbon content makes it difficult to weld or process using standard L-PBF parameters, as the carbon content is easily vapourised and can contaminate the powder surface during the melting process – potentially leading to issues such as internal flaws, porosity and thermal cracks.

Farsoon and NXCMFG have partnered to find a solution for these challenges. A number of tests have reportedly been conducted by Farsoon’s application team to develop processing parameters for the manufacture of parts in H13, considering factors such as the optimal laser power, scanning strategies, stress relief and heat treatment.

Farsoon reports that its optimised parameter set helps to eliminate the thermal cracks which may develop when welding H13 steel and delivers a high relative density of over 99%. The additively manufactured H13 parts achieved in the project are also said to exhibit excellent mechanical properties in comparison to wrought H13 material.

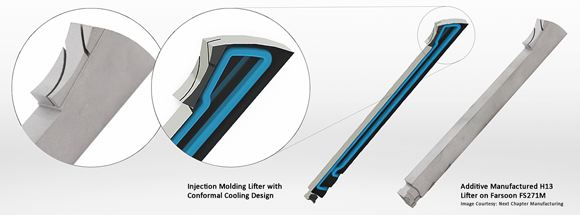

One successful H13 component which the partners have recently developed is a lifter used to cool and separate plastic parts from the core during the injection moulding process. A conformal water circuit design was added to the geometry of the lifter, and the component was Additively Manufacturing on a Farsoon FS271M system. Next Chapter Manufacturing stated that it was able to deliver four replacement lifters in eight days.

The company states that these lifters can be installed directly in the production line, with the new conformal water circuit helping to accelerate the cooling process and eliminate warpage in finished injection moulded parts. The optimised lifters are said to have improved production volume when using the original factory settings, reducing the cycle time from 48 seconds to 30 seconds and achieving a reported annual saving of over $100,000.

“We decided to partner with Farsoon Technologies because its system is open, which means we can develop specific processes that enable us to print H13 and other tool steels efficiently,” stated, Jason Murphy, President of Next Chapter Manufacturing.

“This open parameter system also enables us to do test builds and refine our process to improve robustness and speed further,” he continued. “The technology of the Farsoon machine gives designers a significant amount of additional freedom to provide the most efficient designs for Additive Manufacturing, which other machines do not offer.”