Farsoon and Deep Blue Aerospace collaborate on large-scale rocket combustion chamber manufacturing

February 21, 2024

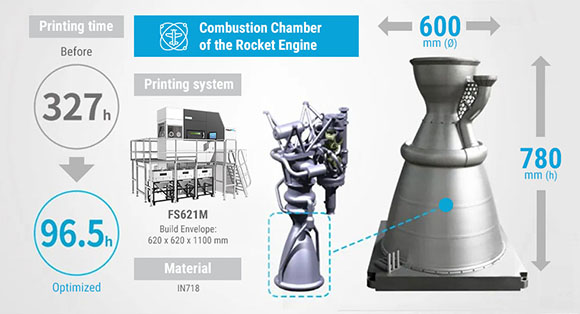

Farsoon Technologies, based in Changsha, China, has collaborated with Deep Blue Aerospace, Nantong, Jiangsu, China, to additively manufacture a 600 x 780 mm rocket engine combustion chamber that has been developed for commercial launch projects.

Together, engineers from Farsoon and Deep Blue Aerospace’s R&D teams addressed key technical aspects, and dedicated months in testing and verification before the completion of the project. The achievements included the successful implementation of machine and process optimisations, targeting high productivity and enhanced quality.

The manufacturing process featured improved items such as the optical system, process parameters, scanning strategy, powder recoating, electrical engineering, and more. After the optimisation, the production time for this combustion chamber was reduced from 327 hours to the current 96.5 hours, representing a significant 338% increase in build efficiency.

The success of this joint R&D project holds significant importance for Farsoon as it aims to enhance the production efficiency in large-format metal Powder Bed Fusion (PBF) solutions. The key research and application innovations in the project included:

- Scanning Strategy – Farsoon implemented advanced multi-laser scanning strategies and a fast-performing algorithm in overlapped areas, addressing challenges in laser power control, galvo system calibration, overlap consistency, and multi-laser task coordination. With optimised parameters, the advanced multi-laser scanning strategy achieves enhanced control of the scanner and galvo, significantly improving communication efficiency by 39% while ensuring internal metallurgical quality.

- Gas Flow – Gas flow design was optimised for the large-format platform to enable smoke removal and smooth operation of multiple lasers, preventing energy dissipation during the down-wind side laser operation generated by smoke and dust during the metal laser sintering process.

- Control System – To facilitate higher efficiency of multi-laser operation, Farsoon’s R&D team optimised the control system to reduce waiting between the lasers and minimise the downtime of the machine. As a result, the multi-laser platform is able to offer higher efficiency in laser output for significantly improved build efficiency.

- Optimised parameters – Given the intricate internal cooling channels within the combustion chamber of the rocket engine, attaining a smooth surface is crucial to minimise flow resistance. Farsoon’s R&D team has customised the processing parameters to achieve the desired high-quality surface that the application requires.

Download Metal AM magazine