Falcontech to install fifty Farsoon metal Additive Manufacturing systems at Super AM Factory

May 28, 2020

Aerospace manufacturing service provider Falcontech co., LTD., Wuxi City, Jiangsu, China, has announced plans for a Super AM Factory which will see the installation of fifty metal Additive Manufacturing machines from Farsoon Technologies, Changsha, Hunan, China. Falcontech reportedly plans to enhance its capacity for series production, and will begin adding further metal AM machines, bringing its total to twenty Farsoon machines by the end of this year.

Founded in 2012, Falcontech has three business units, Metal AM Powder, Metal AM Solution and Advanced Manufacturing. The AS9100-certified company states that it is able to offer a comprehensive portfolio of industrial metal AM solutions, from materials to manufacturing, post-processing, application and servicing.

The company has over seven years’ experience operating Laser Powder Bed Fusion (L-PBF) machines from various international brands, and has reportedly developed a deep in-house expertise in industrial metal AM production. The company’s Super AM Factory initiative aims to expand its capacity and focus on real world production.

Falcontech entered into a long-term partnership with Farsoon by significantly investing in its metal AM systems in 2019. In recognition of this collaboration, Falcontech and Farsoon have jointly worked on a customised large-format metal AM system for aerospace, as well as on the development of Falcontech’s metal AM powders.

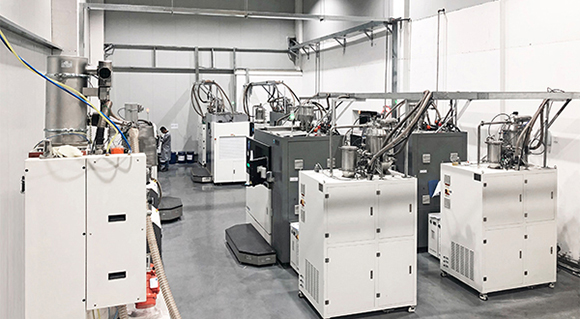

Based on this collaboration, Falcontech has scaled up its manufacturing capacity by installing multiple Farsoon metal systems including an FS421M, FS301M, FS271M, and the customised large-format metal system, which has a build envelope of up to 620 x 620 x 1100 mm. This system is used at Falcontech for the production of large aerospace applications; the company has succeeded in supporting the development and series production of spacecraft components in a number of key aerospace projects.

With the joint effort between Farsoon’s metal AM team and Falcontech, significant technical progress has reportedly been made in areas including productivity optimisation, the achievement of thin wall structures as small as 0.5 mm, improved dimensional-accuracy ± 0.5mm/800mm, improved build surface roughness of Ra 6.3 µm, and metallurgical quality control of parts produced on Farsoon machines.

Said to be due to Farsoon’s ‘Open for Industry’ philosophy, Falcontech reports that it is able to operate with a higher degree of flexibility in parameter settings and material development, which has contributed to the development of a total of twenty material processing parameters for aerospace applications, including multiple types and grades of titanium alloys, aluminium alloys and nickel-based superalloys. This has also enabled the establishment of a processing database for aerospace materials for future development and manufacturing quality control.

“We see an exceptional performance and stability in the Farsoon FS421M metal system via multiple series production jobs since the installation,” stated Yu Hai, General Manager of the Metal AM Solution Unit at Falcontech, “We are thrilled by the high-quality parts manufactured taking advantage of the benefits from Farsoon AM. With the increasing demand of manufacturing orders, Falcontech will further expand our production capacity and improve turnaround time for delivery with more Farsoon metal systems.”