Equispheres adds systems from Aconity3D and Granutools for developing its metal AM powder

March 3, 2021

Equispheres, Ottawa, Ontario, Canada, has added systems from both Aconity3D and Granutools as part of the Equispheres’ lab expansion project. Last year, the company closed a C$30 million investment round to support the lab expansion, increase powder production and continue research & product development of high-performance metal powders for Additive Manufacturing.

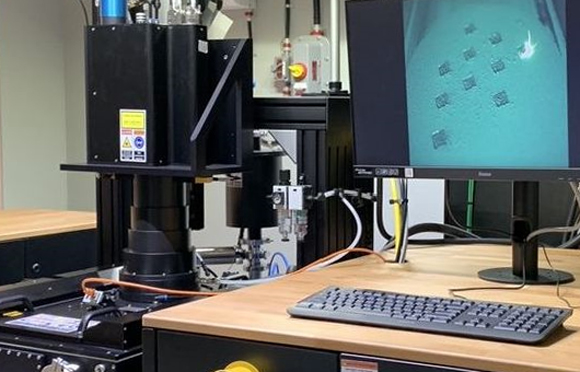

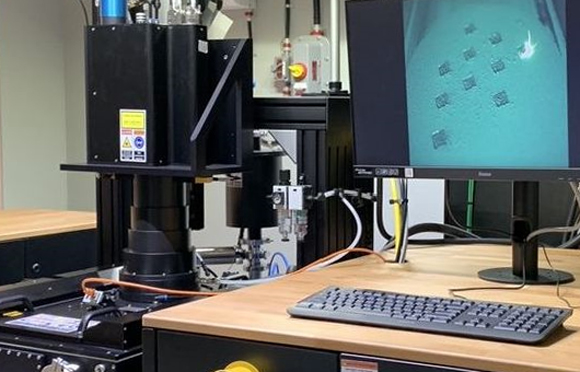

The company has selected an Aconity3D AM machine equipped with a 1000W laser to further research processes and techniques for faster-printed part production. The company also acquired a Granutools’ GranuCharge system, which measures the electrostatic charge created within flowing powder.

Explaining the rationale behind each investment, Evan Butler-Jones, Director of Applications Engineering at Equispheres, stated, “Normally the GranuCharge system is used to conduct basic research at academic institutions. However, we use the tool as part of our QA process. Quality parts require quality powder, and that requires precise instrumentation and measurement systems. The Aconity3D printer was chosen because of its increased precision, high configurability and powerful 1000W laser. This printer enables us to conduct high-speed production parameter optimisation research and testing.”

Kevin Nicholds, CEO of Equispheres, commented, “We pride ourselves on our innovative metal powder solutions, and continued innovation relies on research, testing and data. We are providing our team of skilled engineers, materials scientists and metallurgists with the best tools and systems to ensure Equispheres and our customers are set for success.”