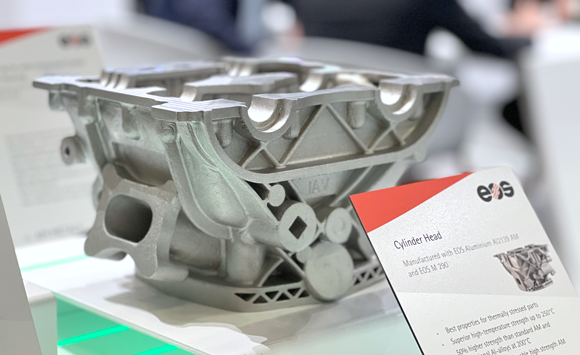

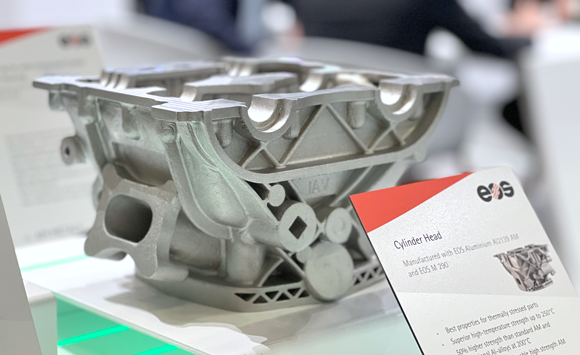

EOS releases new high-strength, lightweight Al2139 aluminium alloy

November 17, 2021

EOS GmbH, headquartered in Krailling, Germany, has announced the addition of EOS Aluminium Al2139 AM, a new material specifically developed for Additive Manufacturing. The alloy is reported to offer high performance in elevated temperatures up to 200°C, good corrosion resistance and is the highest-strength AM aluminium alloy available from EOS.

In its heat-treated state, Al2139 AM achieves a yield and tensile strength of around 500 MPa. Due to a single-step heat treatment procedure, companies can save up to 88% in active heat treatment time, meaning parts can be manufactured faster. Components produced using EOS Aluminium Al2139 AM can also be electropolished and anodised.

The combination of lightweight and strength properties of EOS Aluminium Al2139 AM are said to make it suitable for a range of high-performance and demanding applications such as aviation, transportation, racing and the space industries, while also offering flexibility and improved material and production cost management to the contract manufacturing sector.

Sascha Rudolph, Senior VP EOS Metal Materials stated, “At EOS, we are constantly striving to improve the performance of our customer’s manufactured parts, whilst reducing the amount of material needed and streamlining production processes. EOS Aluminium Al2139 AM is a culmination of those efforts to put new materials innovations in the hands of manufacturers.”

The EOS Aluminium Al2139 AM material and process parameters for the EOS M 290 has a planned release in the first quarter of 2022, with process parameters for other EOS Laser Beam Powder Bed Fusion (PBF-LB) machines released soon after.

EOS will be available for questions on this new material, as well as its complete range, at Formnext, Hall 12.1, D01.