EOS North America to implement Link3D’s MES & AM Workflow Software

December 4, 2018

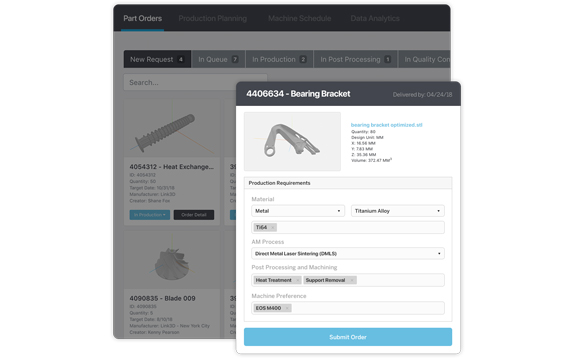

Link3D’s AM-focused Manufacturing Execution System (MES) (Courtesy Link3D)

Software company Link3D, New York City, USA, reports that it is partnering in a proof of concept trial with EOS North America. By implementing the Link3D system internally, EOS North America hopes to be able to offer its clients an enhanced customer experience.

EOS North America routinely performs benchmark studies for its customers from its two technical facilities in Pflugerville, Texas, USA, and Novi, Michigan, USA; this provides the opportunity to understand how AM workflow processes can be managed in a distributed manufacturing model.

Link3D’s AM-focused Manufacturing Execution System (MES) is said to enable users to visualise their AM workflows from order submission through to delivery, connecting two sites digitally and thus improving end-to-end transparency, reducing turnaround times and offering a superior customer experience. According to both companies, this is an excellent fit for EOS’s holistic AM solutions.

Shane M Fox, Link3D CEO, stated, “Link3D is humbled to have its Additive MES solution selected by EOS North America to power its metal benchmarking facilities. We are excited to help increase EOS North America’s operational efficiencies and have our technology integrated into their ecosystem.”

Users of Link3D’s AM workflow software can now see how order submitters can communicate directly with technicians and application engineers to finalise production requirements, costing and quoting, production planning and scheduling, post-processing and quality inspection, delivery – data analytics and more. Further, clients purchasing Link3D MES system will be assured that Link3D’s Build Simulation software for quoting and costing will be time tested by EOS North America. The software will give EOS a scalable solution for itsinternal AM workflow processes.

“We consistently strive to work with cutting edge organisations,” commented Dr Greg Hayes, Director of Applications, EOS North America. “This includes material, software and hardware solutions for the Additive Manufacturing industry. Link3D is one of our choices for software solutions.”