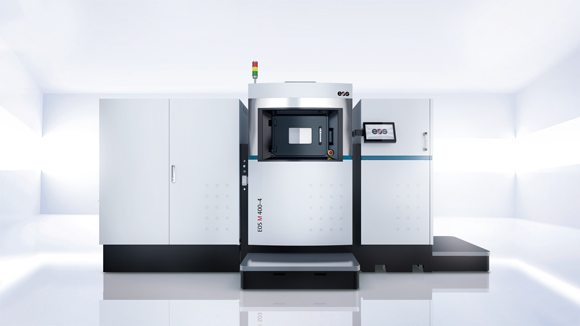

EOS introduces its largest and fastest system for direct metal laser sintering

August 30, 2016

EOS will introduce its latest EOS M400-4 metal Additive Manufacturing system at the IMTS show in Chicago, USA, September 12-17 2016. Designed for industrial applications, the quad-laser system expands the company’s Direct Metal Laser Sintering (DMLS) range and offers increased productivity, part quality and scalability to meet various manufacturing requirements.

“Following our strategy to establish the Additive Manufacturing technology for production in all industries we have developed this pioneering DMLS system. The EOS M 400-4 is a perfect addition to our industrial systems portfolio. It shatters the boundaries of manufacturing as it meets the most demanding requirements of our industry partners in terms of efficiency, scalability, usability and process monitoring,” stated Dr Adrian Keppler, Chief Marketing Officer at EOS.

The EOS M 400-4 expands the high-performance offerings of DMLS systems. It offers a large building volume of 400 x 400 x 400 mm and is equipped with four 400 Watt lasers operating independently in 250 x 250 mm squares each including an overlap of 50 mm. The system builds on the well-established and validated process of the EOS M 290 technology.

“As the system offers a modular platform designed for industrial 3D Printing, it can easily be integrated into existing production environments and the customer set of future innovations,” added Keppler.

As part of the EOS M 400-4 system, the patented EOS ClearFlow process gas management technology ensures optimal and consistent processing conditions. It distributes the process gas in an intelligent way to avoid interference of the lasers with side products of the melting process. In addition, the integrated industrial-grade, recirculating filter system with its long filter lifetime significantly reduces operating times and expenses.

Initially, the materials EOS NickelAlloy HX as well as EOS MaragingSteel MS1 will be available for the EOS M 400-4 and more materials and processes will follow soon. Parameters can be modified to meet individual application requirements using the EOS ParameterEditor.