Elementum 3D and Masten Space complete hot fire testing of PermiAM fuel injector

May 27, 2020

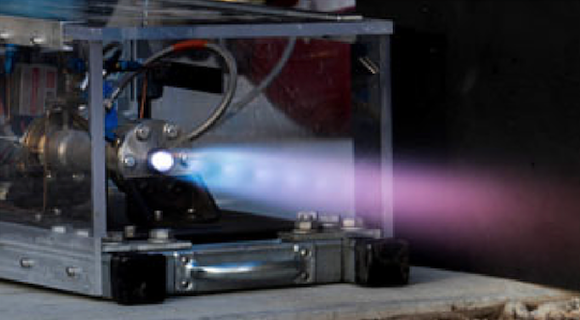

Elementum 3D, Erie, Colorado, USA, and Masten Space Systems, Mojave, California, USA, have completed successful hot fire testing of their jointly-developed PermiAM metal additively manufactured fuel injector, part of the NASA Phase I SBIR project.

Elementum 3D, an Additive Manufacturing research and development company that specialises in the creation of advanced metals, composites and ceramics, began working with aerospace manufacturing start-up Masten Space when the companies partnered on the NASA Tipping Point programme to bring Elementum 3D’s RAM AM process to rocket development by creating an aluminium MMC combustion chamber for the Masten 25k Broadsword Engine.

During that programme, Matthew Kuhns, Masten Space Systems Chief Engineer, became interested in an experimental build developed by Jacob Nuechterlein, Elementum 3D’s President, and the two companies were then able to work together to refine and improve the process so that it can be used for rocket engine and combustion devices.

The result was the patent pending PermiAM Laser Powder Bed Fusion (L-PBF) process, which enables material agnostic transpiration cooling. Some of the most-used engines in NASA’s history, such as the still state-of-the-art RS-25 (SSME) and RL10, use transpiration-cooled injector faces.

In most cases, these transpiration-cooled injectors have been constructed from Rigimesh; multiple layers of a stainless steel mesh pressed and sintered together into a stiff screen. However, Rigimesh cannot be additively manufactured, as its manufacturing methods date back to the era of the Apollo mission.

PermiAM enables complex rocket engine injectors with face cooling to be built using Additive Manufacturing. The technology is said to enable design simplification and cost savings by combining regions of controlled permeability with fully-dense structures within the same injector component. As well as space going engines, this technology could also be applied to other fields, including commercial jet engines or automotive fuel injection.

A key benefit of PermiAM, compared to traditional porosity creation methods, is its ability to form micron-scale porosity, Elementum 3D told Metal AM magazine. This enables high-fluid resistivity and controllable pressure drops, enabling optimised injector performance.

With the ability to vary material density, structural and flow performance may be fine-tuned across the part, enabling novel injector geometries with structural members embedded in porous transpiration-cooled faces or small-scale porous flow paths integrated into structural elements.

Varying the density across the part enables lightweight, yet stiff and strong, parts that can increase engine thrust-to-weight ratio. Cost and schedule savings are realised through the capability to manufacture single parts with varying material properties where, in the past, multiple components needed to be manufactured separately and assembled with a high touch time, long lead times and higher operations costs.

Through work with industry partners, as well as direct quotes from manufacturers for hardware, Masten has determined that the cost savings provided by PermiAM will meet or exceed the 60% mark, which is the criterion used in business to determine when a technology or process is game changing.

Time savings of over 90% are possible when compared to a traditional Rigimesh rocket injector face, and weight savings of 50–70% can be achieved for the hot structure, as PermiAM cooling could allow aluminium to replace Inconel parts.

“This exciting work with Masten is leading us to new and exciting technologies only possible with 3D printing,” Dr Jacob Nuechterlein, Elementum 3D’s President and Founder, told Metal AM. “We see PermiAM making a significant impact on all sorts of industries, from diesel engines to complex heat exchangers to carbon sequestration. Like many space innovations, we are applying our joint technology to a wide variety of terrestrial applications as well.”

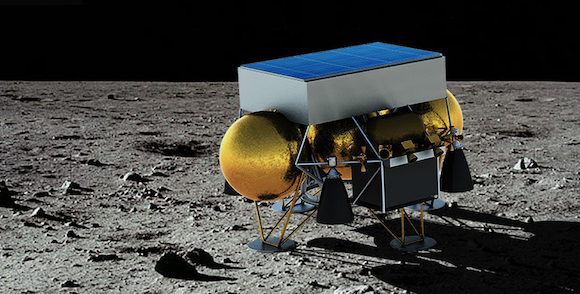

Sean Mahoney, CEO of Masten Space Systems, added, “This collaboration is the prime example of how US industry is staying at the forefront of business. The value of this technology is unlocked where it turns into applications – and that is precisely what Elementum and Masten are doing. This partnership is already helping improve systems here on Earth, and unlocking the Moon for our future.”

The PermiAM fuel injector has been successfully hot fired in Elementum 3D’s AMCopper-100 (pure copper) and A1000-RAM10 materials. Hot fires are pending in its GR-Cop42 and Inconel 625 materials.