Dunlee increases output of additively manufactured tungsten anti-scatter grids for CT systems

May 11, 2020

Dunlee, a distributor of products, solutions and services for the third-party imaging business, headquartered in Hamburg, Germany, reports that it is increasing its output of additively manufactured tungsten anti-scatter grids used in CT systems, to support patient access during the coronavirus (COVID-19) pandemic.

Dunlee is a brand of the Philips Company Group and specialises in medical imaging components including CT, MR and X-ray solutions for OEMs, CT replacement tubes and additively manufactured tungsten products.

The company explains that CT examinations are used to assess respiratory conditions as well as monitor severe COVID-19 cases, making it an important component of COVID-19 diagnosis and assessment. The pure tungsten anti-scatter grids, which are manufactured in Best, the Netherlands, absorb unwanted scatter radiation to improve the quality of CT images. Within Cone Beam CT, Dunlee’s 2D anti-scatter grids are said to provide an improvement in signal-to-noise ratio up to a factor of 1.7 compared to previous solutions.

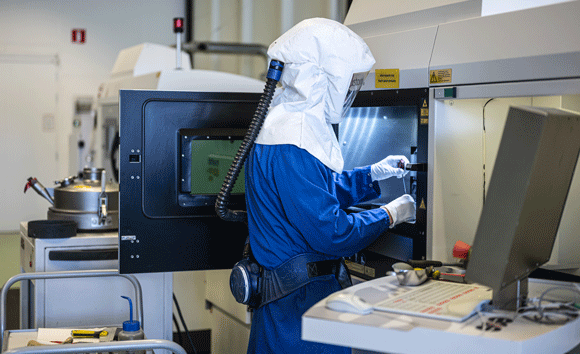

“As a result of the COVID-19 pandemic, we are in operation around the clock, so we are working closely with our long-term partner EOS to obtain new printers while also fine-tuning our existing printers to increase output,” stated Jan Laheij, Global Head of Commerce – Imaging Components, Dunlee. “We are fortunate that we can count on quick response from the EOS maintenance and service team to keep our machines running 24/7.”

Dunlee states that it is also hiring more operators and engineers, and has re-prioritised projects so it can provide anti-scatter grids as quickly as possible to CT system manufacturers. Laheij added, “While the pandemic is impacting our lives and our way of working, our customers remain the focus of everything we do.”