DP Technology’s ESPRIT software supports DED AM

June 1, 2020

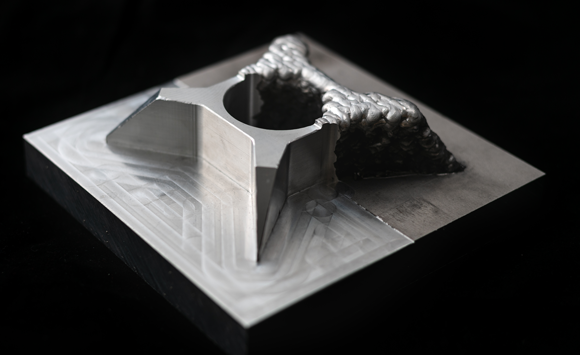

DP Technology, Camarillo, California, USA, developer of the ESPRIT CAM system, reports that its first commercial version of ESPRIT includes support for Directed Energy Deposition (DED) Additive Manufacturing.

ESPRIT’s AM capabilities are said to include the same intuitive user interface that users expect from the software. The product release includes 3-axis, 4-axis, and 5-axis DED support. Combined with the subtractive processes and embedded into a single software, DP Technology states that it brings a full spectrum of support to hybrid manufacturing.

According to DP Technology, its ESPRIT’s DED cycles include Additive Manufacturing simulation and verification, as well as global support from ESPRIT’s technical teams. The company reportedly validated its post-processor through collaboration with major machine manufacturers and educational institutions.

“For more than a decade, we’ve been working on Additive Manufacturing, including research on DED toolpath trajectories and AM thermal simulation,” commented Frederic Vignat, Head of the Additive Department at Grenoble University, France. “ESPRIT’s additive DED solution is the result of the close collaboration between DP Technology, the industry’s most trusted CAM solution provider, and Grenoble University, the world’s leading research institution on additive DED technology.”