DNV and Siemens Energy create quality assurance platform for Additive Manufacturing

July 6, 2023

DNV, a risk management and quality assurance provider based in Oslo, Norway, and Siemens Energy’s global Additive Manufacturing business unit are joining forces to create a quality assurance platform for the Additive Manufacturing industry. The collaboration aims to accelerate commercial AM production with quality control at every stage in the manufacturing process.

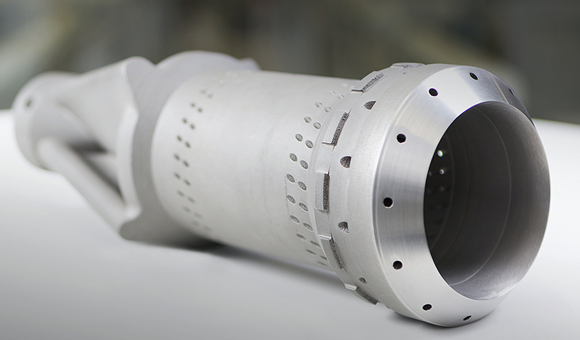

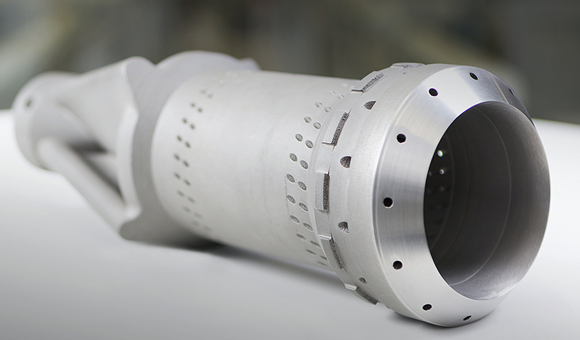

Siemens Energy has developed the first generation of AM Cockpit platform providing automated, reliable quality control of the metal Additive Manufacturing process. In turn, DNV has developed the Independent Quality Monitor (IQM) platform – a customer portal that continuously quality-assures digital solutions. By combining these two solutions, DNV can launch a commercial solution for the AM manufacturing industry, ensuring that AM parts can be easily compared to the master print as well as making automated and remote process certification possible.

The AM Cockpit collects sensor data streams and powder bed images from the manufacturing process in Powder Bed Fusion (PBF) Additive Manufacturing, it then generates a digital summary of each printed part, highlighting problematic areas of the build.

In parallel, the IQM has been developed as part of the EU-project InterQ, aiming at zero-defect manufacturing. The solution reportedly monitors data quality continuously through newly developed algorithms and compliance logic.

By industrialising the combined solution, DNV aims to become the global energy sector’s preferred choice for digital risk management.

“Succeeding in AM industrialisation relies on a successful digital transition. The combination of the AM Cockpit and the IQM is a significant step forward for Additive Manufacturing,” shared Klas Bendrik, Chief digital and development officer at DNV.

Stian Gurrik Senior Engineer and AM specialist, added, “The benefits of 3D-printing, when used properly, can include reduced material waste, quicker production, cost savings and the ability to produce complex and customised parts.”

The digitalised quality assurance method of the AM Cockpit and the IQM looks to allow the quality of the manufacturing process to be visualised so that the end user can be confident that the process meets the necessary quality standards.

“With decades of experience in industrialising Additive Manufacturing, Siemens Energy is an excellent partner for DNV in advancing quality assurance of additively manufactured parts,” said Manish Kumar, Head of Business Development, Strategy and Sales of Siemens Energy Additive Manufacturing Business.

Download Metal AM magazine