Divergent Technologies acquires Sigma’s software business to integrate with DAPS

October 17, 2023

Divergent Technologies, Inc, located in Torrance, California, USA, reports it has entered into an agreement to purchase all of the in-process quality assurance technology suite assets, including associated software and intellectual property, from Sigma Additive Solutions, Inc, based in Santa Fe, New Mexico. Sigma announced in September that it was exiting the Additive Manufacturing software business, having acquired a travel technology company.

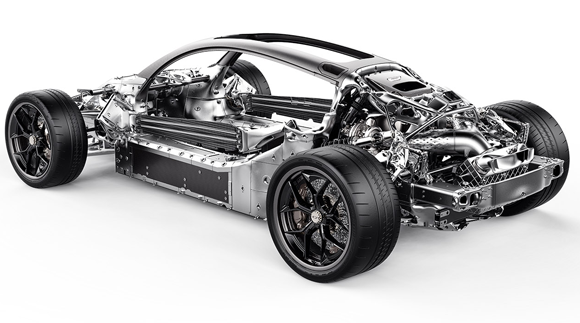

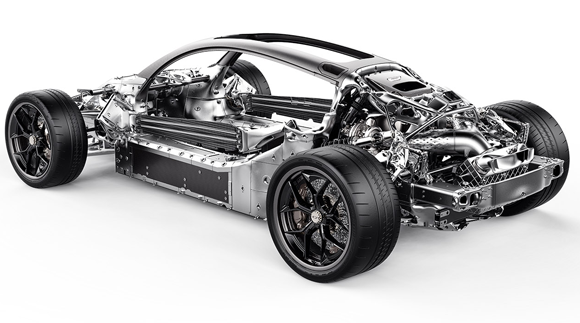

Divergent is the inventor of the Divergent Adaptive Production System (DAPS) and parent company of the performance automotive company Czinger Vehicles, maker of the Czinger 21C hypercar featuring over 350 AM components. The acquisition is expected to further enhance the efficiency and quality control of DAPS, whilst strengthening the company’s intellectual property coverage the area of in-process monitoring.

DAPS is a comprehensive software-hardware production system designed to replace traditional design and manufacturing solutions. Using AI-driven generative design software, DAPS computationally engineers structures and develops novel materials. It then employs Additive Manufacturing to bring these structures to life and utilises automated fixtureless assembly to create multi-part assemblies. The system transitions between manufacturing different structures, such as automotive chassis and aircraft fuselages, with zero downtime between builds. The hardware in the factory is product agnostic and fully software-defined.

Divergent utilises this system to provide the automotive, aerospace, and defence industries with next generation products as a certified Tier 1 supplier. Its customer base includes over seven blue-chip automotive companies, such as Aston Martin. In the aerospace and defence sector, Divergent collaborates with six US government contractors on various applications.

Divergent’s acquisition of Sigma’s in-process quality assurance (IPQA) tools, along with all the associated software and IP, allows Divergent to smoothly integrate Sigma’s technology into the DAPS software platform. This integration also takes advantage of Sigma’s foundational patents.

“This strategic acquisition is of great significance as Divergent deploys DAPS structures across the automotive, aerospace, and defence industries,” stated Lukas Czinger, COO and co-founder of Divergent and Czinger Vehicles. “Sigma’s foundational IP centred on in-process monitoring will be integrated into and expanded on within the Divergent portfolio. The core software will be seamlessly applied to our Additive Manufacturing module and will further enhance Divergent’s industry leading Additive Manufacturing quality management system. Ultimately, this acquisition further supports our confidence in suppling structures for safety-critical and mission-critical applications.”

Jacob Brunsberg, CEO of Sigma Additive Solutions, added, “We have found a great home for Sigma’s technology and are extremely excited to see Divergent build on the foundational work from Sigma in connection with the DAPS platform. This is a significant step forward for digital manufacturing quality.”

Download Metal AM magazine