Developers of extreme high-speed laser material deposition process receive innovation award

July 25, 2018

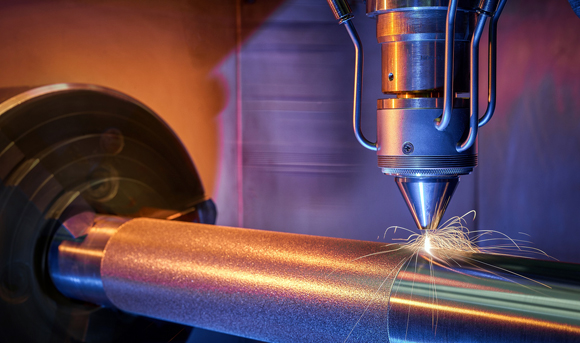

EHLA can be used to coat, repair or additively manufacture components in a particularly economical and environmentally friendly way (Courtesy Volker Lannert / Fraunhofer ILT)

The research team responsible for the development of Extreme High-Speed Laser Material Deposition (EHLA) was recently awarded first prize in the biennial Berthold Leibinger Innovationspreis 2018, an award recognising innovations in the application or generation of laser light in any industry or field of technology. Consisting of members from the Fraunhofer Institute for Laser Technology (ILT) and the RWTH Aachen University, Germany, the team will receive the award on September 21, 2018.

EHLA can be used to coat, repair or additively manufacture components in a particularly economical and environmentally friendly way. While in conventional laser deposition, the laser generates a weld pool on the surface of a component and fuses the metal powder, coaxially added simultaneously, to create the required shape. The powder then fuses with the surface of the part, gradually forming a protective coating.

By contrast, in the EHLA method, the laser strikes the powdery filler material above the weld pool, heating the material nearly to its melting point before it makes contact with the component. Consequently, the particles melt faster in the weld pool. This makes it possible to use energy much more efficiently.

Whereas normal laser deposition welding can coat only 10 – 40cm2 per minute, the EHLA method is said to achieve rates of over 250cm2 per minute. In addition, much thinner coatings with layer thicknesses of 10–250 µm are now possible. EHLA also permits a much finer laser focus, rendering the process considerably more energy-efficient, and can be used as an alternative to hard chrome plating chromium (VI) compounds or thermal spraying.

The EHLA research team includes Dr.-Ing. Andres Gasser and Dipl.-Ing. Thomas Schopphoven, Fraunhofer ILT, and Dipl.-Ing. Gerhard Maria Backes, Chair of Digital Additive Production DAP, RWTH Aachen University. Schopphoven, who is Head of the Productivity and Systems Engineering team in the Laser Material Deposition Group at Fraunhofer ILT, represented the research team during the jury session at the final stage of the Berthold Leibinger Innovationspreis, where he presented and explained their innovation alongside the seven other international teams in the final.

This is the latest in a series of prizes awarded to the developers of EHLA, following their receipt of the Joseph von Fraunhofer Prize in 2017 and the Steel Innovation Prize in 2018. It consists of a €50,000 endowment, which will be presented to the team in a ceremony set to take place at the headquarters of the TRUMPF Group in Ditzingen. Schopphoven commented, “In the laser industry, this is one of the world’s top-class awards. We are extremely pleased about the recognition of our work on energy- and resource-efficient production with laser light.”

EHLA has also found commercial success; since 2015, Dutch-based IHC Vremac Cylinders B.V. has employed the technology to coat hydraulic cylinders for worldwide offshore use. These cylinders have lengths of up to 10 m and diameters of up to 500 mm, and are coated with wear- and corrosion-resistant alloys which must meet the highest demands. ACunity GmbH, Aachen, a spin-off of Fraunhofer ILT, is targeting the offshore market in China and recently delivered three large EHLA systems to China’s Hebei Jingye Additive Manufacturing Technology Co., Ltd. for the environmentally-friendly coating of offshore hydraulic cylinders.

Schopphoven believes that further applications could be identified in the automotive industry. He stated, “the EHLA process is particularly suitable for the automotive industry, such as for the coating of brake discs, which were previously difficult to coat because of the high loads and high demands on efficiency and environmental friendliness.”