Desktop Metal showcases its enhanced Production System for high volume Additive Manufacturing

November 13, 2018

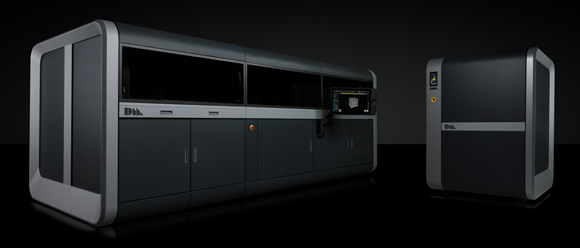

Desktop Metal has expanded the capabilities of its Production System (Courtesy Desktop Metal)

Desktop Metal has announced a number of major advancements and expanded capabilities to its Production System, the company’s metal Additive Manufacturing machine developed for mass production of complex metal parts. At formnext 2018, November 13-16, Frankfurt, Germany, the company showcased the updated system and displayed a wide range of metal additively manufactured parts produced on the new machine.

The installation of the first Production System is scheduled for Q1 2019 to a Fortune 500 company among Desktop Metal’s early Pioneer customers. Additional customer installations at major automotive, heavy duty and leading metal parts manufacturers will follow throughout 2019, with broad availability in 2020.

“We are excited to provide the international engineering and design community with deeper insights into the power of the Production System with updated innovations and an extensive display of metal parts to be publicly shown for the first time this week,” stated Ric Fulop, CEO and co-founder of Desktop Metal. “As we continue to expand our list of global customers and partners, companies that are turning to the game-changing technology available with the Production System, and installations set to begin rolling out in the coming months, Desktop Metal is looking to further shift the industry beyond prototyping to now include full scale metal manufacturing.”

Powered by Single Pass Jetting technology, the Production System is said by Desktop Metal to be more than four times faster than any binder jet competitor and offers a hundred times speed improvement over any laser-based system. Since it was first introduced, advancements to the technology and capacity of the Production System have expanded to include:

- Accelerated printing speeds to 12,000 cm3 per hour

- Expanded build volume of 750 x 330 x 250 mm, a 225% improvement, designed for higher throughput and efficiency

- Two full-width print bars, advanced powder spreaders and anti-ballistic system that work to spread powder and print in a single quick pass across the build area

- Use of 32,768 piezo inkjet nozzles that enables binder chemistries to print an array of metals – including tool steels, low alloy steels, titanium, and aluminium – at a rate of 3 billion drops per second

- Offers a binder jet system with an industrial inert environment, including gas recycling and solvent recovery, to safely print reactive metals in mass production

- Capability to print more than 60 kilograms of metal parts per hour.

Examples of components produced on the Production System

In addition to the Production System, Desktop Metal also showcased printed metal parts for applications across industries, demonstrating the range and complexity now achievable by the system.

Spauger bit

The spauger bit, by Milwaukee Tool®, features complex geometry traditionally requiring multiple manufacturing steps to produce, including time-consuming, dedicated setups for milling, turning and grinding operations. The Production System has reduced the number of steps in spauger manufacturing from more than twenty steps to four, and producing as many as 1,400 spauger bits per four-hour build.

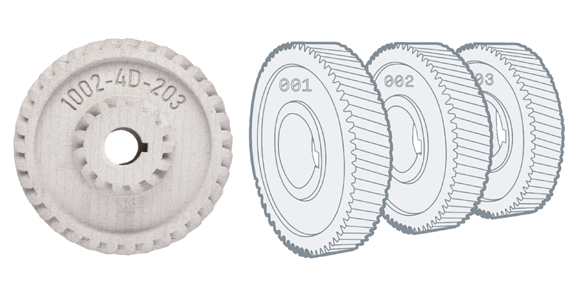

Mass customisation

The Production System is capable of mass customising batches of generative designed gears at varying amounts with mass production efficiency. Instead of needing to post-process each part using laser or electrochemical etching, ink marking, or dot peening, parts can now be printed with serial numbers – or other customisation detail – in place, rending an entire build volume of unique parts with no need for post processing.

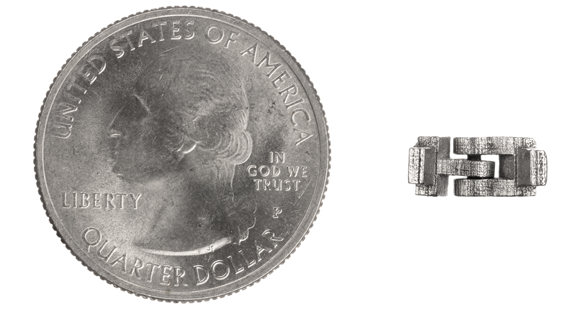

Pre-assembled hinge

Standard hinge designs, such as those used with eye-glasses, typically consist of two leaves that are bound by, and revolve around, a central pin. Assembly of these small components can be time-consuming in high volume, and often require precision engineering tools and equipment to manufacture. The Production System is able to print more than 45,000 pre-assembled 12 x 5 x 6 mm eye-glass hinges in a single four-hour build. The hinge featured at formnext was manufactured with the pin printed directly into the knuckle of the mating leaf – eliminating assembly time and reducing risk of disassembly with use over time.