CoreTechnologie 4D_Additive update to easily repair STL and scan data

April 26, 2022

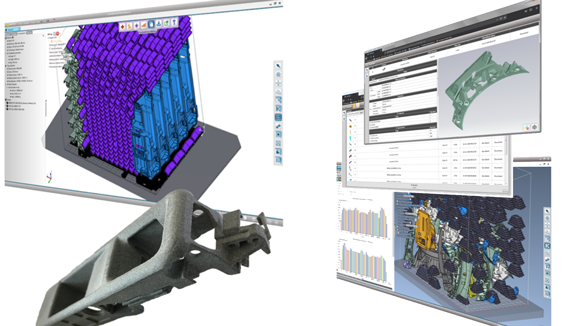

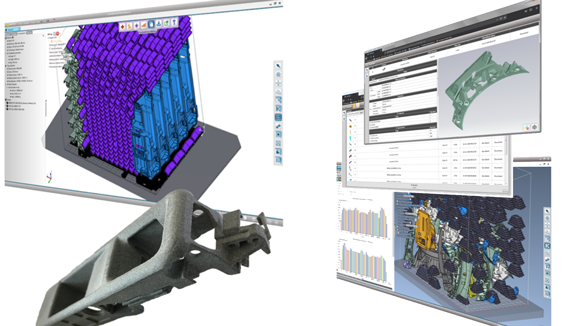

CoreTechnologie, headquartered in Mömbris, Germany, has added ‘Marching Cube’ and ‘Mesh Simplification’ to its Additive Manufacturing software 4D_Additive. This new tool gives users the ability to simplify tessellated files and turn them into closed solids quickly, allowing any type of triangulated 3D model to be corrected and prepared for Additive Manufacturing.

Modern Additive Manufacturing is based on accurate CAD data, but, more and more often, this data is generated with a 3D scanner. The quality of STL data is often poor and not suitable for Additive Manufacturing or other subsequent processes. To ensure error-free slicing and building, it is necessary to repair errors on STL models and send closed solid models to the Additive Manufacturing machines. In addition, scanned parts often have file sizes of several gigabytes due to the high number of very small triangles – especially if several scanned files are to be additively manufactured in the same build job, the size of the data that must be sent to the machine can become a real problem.

The 4D_Additive 1.4 update now has functions to close the tessellated models into ‘watertight’ solids and intelligently mesh reduction functions in order to reduce the number of triangles without losing accuracy. Marching Cube and Mesh Simplification allow any type of triangulated, mostly STL data, to be automatically corrected and simplified at the touch of a button.

With the Marching Cube function, faulty STL models and scan data can be repaired and transformed into closed solids. The Marching Cube function combines a ‘voxelisation’ of the parts with their repair, whereby the size of the voxel (i.e., cube) and, thus, the fineness can be defined by the user. After the adaptive filling of the part volume with voxels – the so-called ‘voxilisation’ – a closed 3D mesh is generated. The 4D_Additive software thus repairs models with hundreds and thousands of triangulation defects automatically within seconds.

In addition, the user has access to various options for the intelligent reduction of triangles. By defining a maximum angle between the triangles – the maximum chord deviation – by percentage reduction or by defining the desired number of triangles the file size and complexity of triangulated models can be reduced easily.

The use of the two new functions makes it possible to repair various types of scanned parts without manual effort, thus creating additively manufactured solids with a reasonable file size and resolution from scans and faulty STL models in a very short time. In the future, this technology is hoped to enable a significant simplification of the scanning and Additive Manufacturing process.