Conflux’s additively manufactured heat exchangers boost AMCM M 4K performance

October 27, 2023

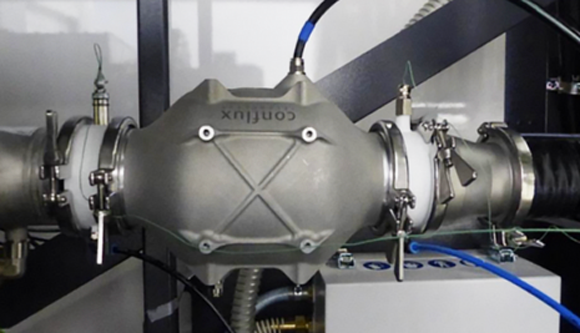

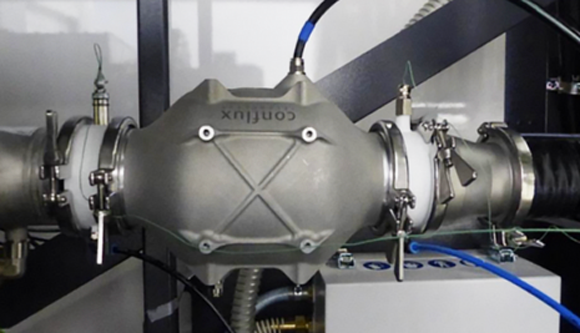

Conflux Technology, located in Geelong, Australia, has reported it is additively manufacturing gas-liquid heat exchangers for use in the upgraded thermal management systems now used in MCM M 4K Additive Manufacturing machines. AMCM, an EOS Group company based in Starnberg, Germany, reports that the new Conflux heat exchangers lower the temperature of argon gas by a few degrees Celsius during a build job, allowing the M 4K to operate at a high efficiency with longer build times and high-speed processing.

“Conflux’s team of engineers have developed a unique capability to utilise Additive Manufacturing techniques to deliver superior heat transfer performance,” stated Martin Bullemer, Managing Director of AMCM. “Embedding Conflux’s additive manufactured heat transfer technology enables us to continue pushing the boundaries of what our 3D metal printing machines can do.”

Due to the success of the new heat exchanger in the M 4K system, AMCM plans to apply the same principle to enhance its recently announced M 8K system. The M 8K system features a large build volume of 800 x 800 x 1200 mm, and is designed for the production of large-scale components for aerospace and other demanding applications..

“Bringing our heat exchanger expertise to the Additive Manufacturing machine tool industry has been a long-held ambition of mine and is now realised with the successful adaptation of our Conflux Core™ technology into AMCM’s premier platform,” added Michael Fuller, CEO of Conflux Technology. “Scaling our business throughout the broader industrial machine sector with our highly efficient heat transfer technology through compelling business cases and uncompromised quality is a key focus for our team.”

Read the full case study here.

Download Metal AM magazine