AMCM’s new M 8K metal AM machine to build large-scale rocket engine combustion chambers

September 28, 2023

AMCM, an EOS Group company based in Starnberg, Germany, has announced details of its M 8K Laser Beam Powder Bed Fusion (PBF-LB) metal Additive Manufacturing machine, expected to be released towards the end of 2024. The M 8K will have a build area of 800 x 800 x 1200 mm and, with eight lasers, is aimed at the production of large-scale components for aerospace and other demanding applications.

AMCM reports it has been working with ArianeGroup on the development of rocket engines that will be used to power the new Ariane 6, and has received funding through a National Grant to help improve the rocket’s competitiveness. The company expects to use the new M 8K to build the rocket’s Prometheus engines, having already proved the performance of its AM technology through its smaller M 4K machine.

“We needed to find a partner who was willing to work with us to push the boundaries of what’s possible,” stated Jan Alting, Head of Future Propulsion of ArianeGroup. “This is literally AMCM’s DNA, who have already built an excellent reputation having multiple M 4K systems in this industry. ArianeGroup projects must meet ESA’s strict requirements to be approved for launch. As a result, we place the greatest value on part quality, eg, material microstructure and surface roughness.”

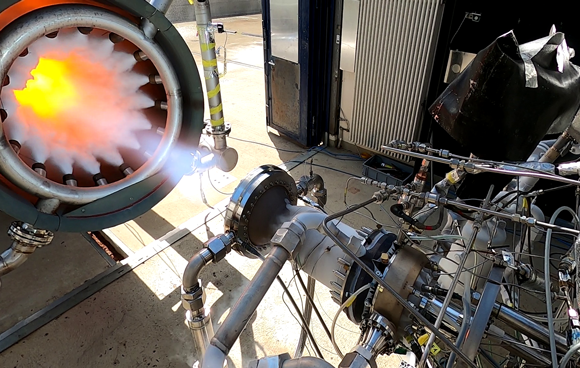

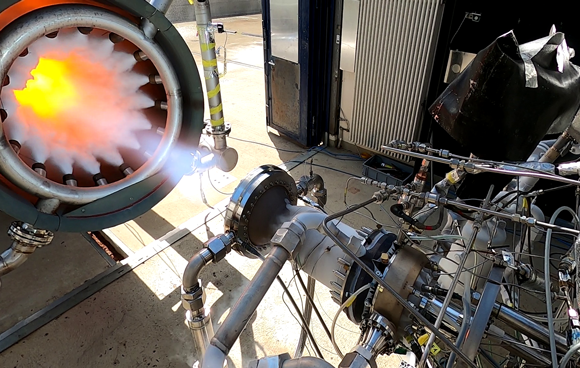

AMCM has already built the combustion chamber for a launcher upper stage engine as part of the ESA’s Expander-Cycle Technology Integrated Demonstrator (ETID) project. This was produced on the M 4K machine, which has a build area of 450 x 450 x 1000 mm and is powered by four 1 kW lasers.

In June this year, ArianeGroup completed the final test of the reusable Ariane 6 Prometheus engine for the Themis rocket stage demonstrator. The engine, with almost 70% of its components built using Additive Manufacturing, successfully performed a twelve-second burn. Typical of ArianeGroup’s portfolio of large rocket engines, the Prometheus combustion chamber is built from CuCr1Zr and measures over 1000 mm tall, with a maximum diameter of 800 mm.

“Designing a system of this size involves a whole range of challenges. The excellent laser, scanner and optics design with our tried-and-tested beam sources is based on decades of process expertise from EOS,” explained Martin Bullemer, Managing Director at AMCM. “The build volume is 4 X that of the M 4K, which also means mass. Therefore, the z-axis of the system must be able to move up to 5 tons of powder with highest precision.”

Other challenges include maintaining a uniform protective gas atmosphere and a reliable, uninterrupted powder supply. The process gas needs to evenly cover the large powder surface of 0.7 m2, while ensuring that fumes are safely dissipated to prevent any degradation in quality during long manufacturing times.

The importance of material supply is often underestimated, explained Bullemer: “For printing up to 1.2 m tall parts with high productivity and quality, powder management is key. Reliably feeding tons of metal powder over several days is no walk in the park. You do not want to interrupt the process in any case.“

As parts become larger and build runs become longer, process control and validation become more crucial. However, X-ray computed tomography remains a commonly used method for inspecting the structural integrity of additively manufactured parts. In the M 8K, AMCM states it will integrate the latest technology from EOS Group – including SmartFusion and EOSTATE Exposure OT (optical tomography). This integration aims to enhance in-process quality assurance and process monitoring, ultimately reducing the need for extensive subsequent testing.

“Metal printing offers the potential to make the rocket engine manufacturing process more flexible, less expensive, and faster. Our new M 8K system will be operational within a year. We have promised ArianeGroup the first printed combustion chambers before the end of 2024,” concluded Bullemer.

Download Metal AM magazine