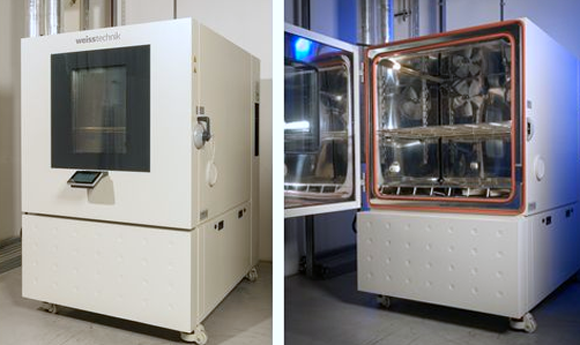

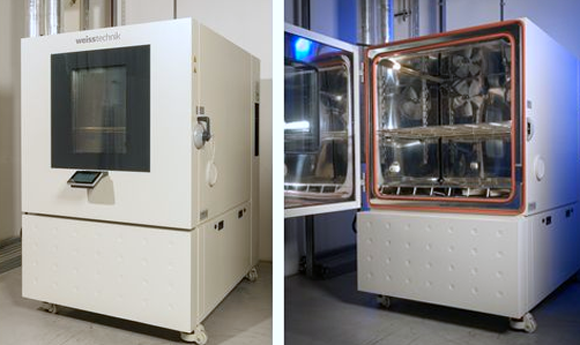

Climatic chamber for conditioning metal powders installed at TWI

July 27, 2022

TWI, Cambridge, Cambridgeshire, UK, has acquired a climatic chamber from Weiss Technik, Germany, for the conditioning of metal powders for Additive Manufacturing. The new climatic chamber will be used to assess the influence of storage conditions, such as the effect of humidity and temperature, on AM metal powders as part of IUK funded Scalable AM Rule Creation & Dissemination (SAMRCD) project.

The climatic chamber is capable of simulating various environmental conditions, due to its extended temperature and humidity ranges. Additionally, the climatic chamber allows for rigorous checking and regulation of testing parameters to ensure simulation conditions meet the necessary requirements.

The SAMRCD project operates through a consortium led by Authentise Ltd, London, UK, having been awarded a competitive grant by the UK Research and Innovation’s (UKRI) Transforming Foundation Industries challenge, delivered by Innovate UK. The consortium includes ICD, Materials Processing Institute, TWI and Photocentrics.

TWI will also use the new climatic chamber to help customers simulate a particular environment for metal powders, simulate storage or operating conditions. It will help assess corrosion resistance, evaluate thermal stress and distortions, and understand coating thermal shock response.