China’s Avimetal AM offers over two hundred metal powders

March 22, 2023

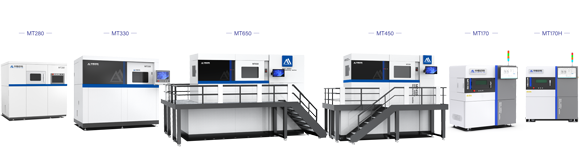

Avimetal AM, a subsidiary of Jingcheng Electromechanical, Beijing, China, entered the metal Additive Manufacturing equipment market in 2021, adding four new Laser Beam Powder Bed Fusion (PBF-LB) AM machines to its portfolio in 2022. In addition to machine development, the company also produces a wide range of metal powders tailored to Additive Manufacturing and other metal powder-based technologies, including Metal Injection Moulding (MIM), Hot Isostatic Pressing (HIP) and Powder Metallurgy (PM).

Established in 2015, the state-owned company now has three facilities in China, two of which are dedicated to metal powder production and one for building its metal AM machines. Its powder production equipment includes Vacuum Induction Melting and Inert Gas Atomisation (VIGA), Electrode Induction Melting Inert Gas Atomisation (EIGA), Plasma Rotating Electrode Process (PREP) and Plasma Atomisation (PA).

In total, Avimetal offers more than 200 metal powder alloys, and has a current annual capacity of over 5,000 tons. The range includes titanium alloy powders such as CpTi, Ti6Al4V, Ti6Al4VELI, Ti-6.5Al-1Mo-1V-2Zr, Ti-6Al-2Sn-4Zr-2Mo-0.08Si, TiAl4822; superalloy powders including In718, In 625, Hastelloy X, M247, Haynes188, NiTi50; aluminium alloy powders such as AISi7Mg, AISi10Mg; refractory metal powders including Ta, W, Mo; cobalt-chromium powders such as CoCrW, CoCrMo, CoCrMoW as well as steel powders including 18Ni300, 316L, 17-4PH. Customised grades of metal powders are also available.

Over the years, Avimetal has provided metal AM machines, metal powders, and process technology services to more than 5000 customers worldwide. The company’s largest PBF-LB machine now boasts a build volume of 1250 x 1250 x 1500 mm, with a maximum number of twelve lasers, significantly improving the capacity and production efficiency of large and complex structural components.

As well as equipment an metal powders, Avimetal also offers technical training, component design optimisation, modeling, heat treatment and surface treatment solutions.

Download Metal AM magazine