ČEZ and Škoda JS expanding Additive Manufacturing in nuclear power plants

February 28, 2023

ČEZ Energy Group, an electricity and heating conglomerate headquartered in Prague, Czechia, and Škoda JS, a nuclear engineering company acquired by ČEZ in November 2022, are reported to have produced some 4159 metal and plastic additively manufactured parts in the past year, helping avoid delays caused by disrupted supply chains and boosting energy independence.

According to World Nuclear News, supply chain disruptions from the pandemic and the war in Ukraine meant the company had to find a way to produce replacement parts without having to wait months for traditional manufacturing. The companies stated that “during the first year the deployment of parts from 3D production contributed to reducing downtime and increasing power plant production, without affecting the safe supply of electricity.”

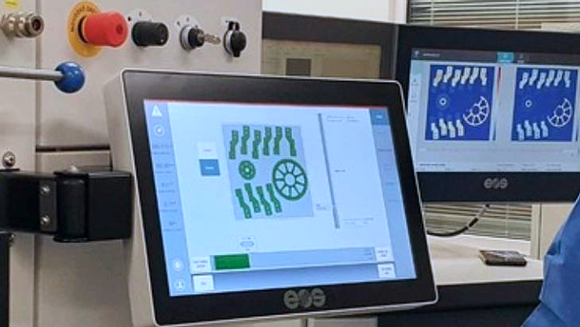

Škoda JS has Additive Manufacturing machines for the production of large metal parts at its plant in Pilsen, with smaller AM machines at both Czech nuclear power plants. Although it has capacity for producing metal parts weighing up to 600 kg, it has thus far focused on additively manufacturing plastic and smaller metal parts.

“The choice of 3D printing technology depends on the material and requirements for the given part,” explained František Krček, CEO of Škoda JS. “A shaft is always better and cheaper to produce using machine tools. For parts with a very complex shape, such as a gear wheel for a gearbox, it is better to use 3D technology.”

ČEZ mainly uses AM for non-nuclear components in power plants, but stated it would like to expand the use of AM parts to nuclear applications.

“It is another of the steps…to the strengthening of our independence in the supply of spare parts and the planned operation of the nuclear units for at least sixty years,” stated Bohdan Zronek, ČEZ board member and director of the nuclear energy division. “Thanks to 3D technology we can produce new, completely identical components, which is important in the event that the supplier no longer exists or does not produce the part.”

Download Metal AM magazine