CERN adopts Simufact Additive software for Selective Laser Melting simulation

May 24, 2018

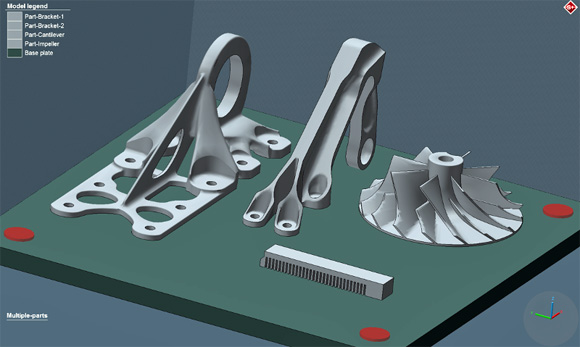

Simufact Additive offers scalable process simulation for the optimisation of laser Powder Bed Fusion (PBF) AM processes (Courtesy Simufact Additive)

The Mechanical and Materials group at the European Organization for Nuclear Research has reportedly chosen Simufact Additive to simulate the Additive Manufacturing process for High Energy Physics applications. The software will be used to predict the deformation of parts in applications such as superconducting magnets and Radio-Frequency (RF) components, produced in CERN’s Additive Manufacturing workshop.

Simufact Additive, a product of Simufact, Hamburg, Germany, offers scalable process simulation for the optimisation of laser Powder Bed Fusion (PBF) Additive Manufacturing processes. The software offered includes simulation of all the key metal AM process steps, starting with part production and followed by heat treatment, cutting the part off the build plate and removal of support structures, plus heat and pressure combined processes (HIP).

AM process simulation provides information about potential distortions and residual stresses in the component ahead of manufacturing, and the results can serve as a basis for the user to meet production tolerances by employing appropriate countermeasures before the part is printed. Romain Gérard, AM engineer at CERN, explained, “Predicting deformation is key to achieve first-time-right accurate parts, especially for parts made with expensive materials such as niobium developed for Superconducting RF application.”

Dr Hendrik Schafstall, Managing Director and CTO at Simufact Engineering, stated, “We regard CERN as a flagship customer because of the level of expertise they instil in our growing academic community.” Following the launch of the product just fifteen months ago, Simufact reports that it has built up a broad user base for Simufact Additive. The software is used by more than sixty customers involved in academia, aerospace, and the automotive, medical technology and AM services industries.