Castor Technologies launches software to identify and optimise components for AM

November 11, 2020

Castor Technologies Ltd, Tel Aviv, Israel, has launched CASTOR Enterprise, a proprietary software which is said to enable manufacturers to automatically reduce costs, by utilising the benefits of industrial Additive Manufacturing.

The company explains that CASTOR Enterprise is an on-premises solution which automatically identifies cost reduction opportunities out of thousands of parts and assemblies at once, and delivers recommendations for re-designing parts for Additive Manufacturing (DfAM).

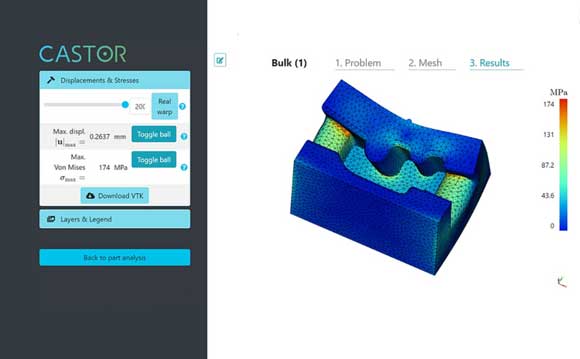

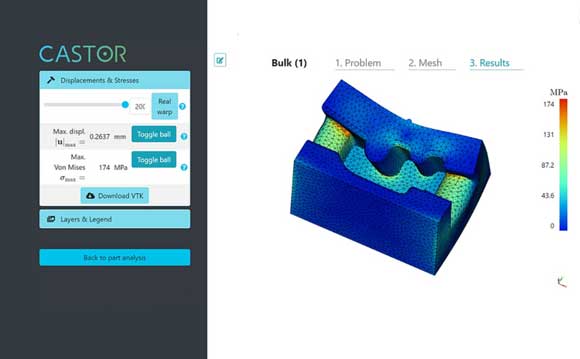

The software is said to be based on the feedback derived from 30,000 parts analysed over the last eighteen months by more than eighty companies. Amongst its features are the part’s’ consolidation and weight reduction identification capabilities, using a fast Finite Elements Analysis, states Castor Technologies.

“We have seen our customers’ need for a solution that not only reveals the ‘low hanging fruits’ out of an existing design but also identifies opportunities for Design for AM,” commented Omer Blaier, co-founder and CEO of Castor Technologies. “With CASTOR Enterprise, we now provide a sophisticated tool which identifies those small changes that can have a huge impact on the company’s bottom line.”

According to the company, its new software aims to make it easier for AM oriented engineers at companies who manufacture low volume/high mix hardware products. The software is said to be built in a way that allows advanced users to modify almost every default figure it sets, such as customised cost estimation calculations, material properties sensitivity, operational costs from various points of the supply chain, such as inventory, shipment, labour costs, and more. It is PLM/ERP integration-ready and available on-premise, completely off-line.

The advanced capabilities of CASTOR Enterprise are said to lie on four pillars:

- Geometry limitations Analysis; based on minimum wall thickness and support material

- Material properties Analysis; comparing the additively manufactured parts’ mechanical properties to traditional manufacturing material properties

- Structural analysis; considering external loads acting upon parts

- Financial break-even point analysis vs. traditional manufacturing methods

Blaier added, “By automating the screening process of thousands of parts we save hours of AM professionals’ manual work. By quickly providing deep insights that can be translated into actionable decisions, we bring manufacturers closer to maximising the potential profit from 3D printing.”