BMW uses its automotive expertise for Additive Manufacturing of custom bobsleigh shoe spike plates

February 27, 2024

As technology partner of the German Bobsleigh, Luge, and Skeleton Federation (BSD), the BMW Group is utilising its Additive Manufacturing expertise, gained from the development and manufacturing of automotive components, to create high-performance customised spike plates for shoes that will be used in the 2026 Olympic Winter Games.

In conventional bobsleigh shoes, defined rows of nails are permanently attached to the toe area of the soles. These nails cannot be replaced or moved, meaning that once the nails have worn out, the shoe needs to be replaced. The solution that BMW and the BSD are working on is based on track and field shoes, for which threads for screw spikes are used to attach spike plates on which the spike nails can largely be distributed without restriction.

This adaptation combines several advantages, including a wider selection of shoe styles. Further, the material and geometry of the plate, as well as the placement of the spike nails, can be used to vary the rigidity and, above all, the power transmission to the ice. With respect to individual running styles as well as the different running paths that the various positions entail – especially in a four-man bobsleigh – this enables better acceleration than standard spikes could ever make possible.

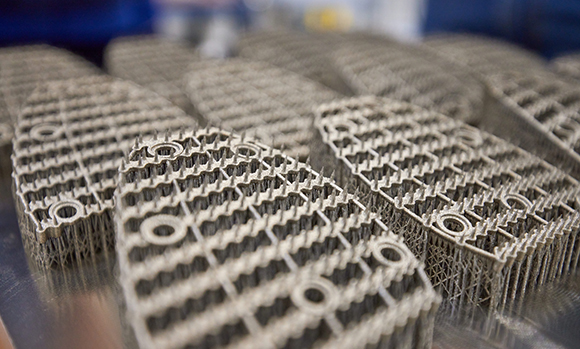

In practice, this means that customised spike plates have to be designed and manufactured for each athlete, which makes Additive Manufacturing an obvious choice.

“We have been using 3D printing to make components for prototypes, customised one-offs, as well as for series production for more than thirty years,” stated Claudia Rackl, BMW Group Additive Manufacturing Projects & Qualification. “The major advantages of 3D printing are the time and cost savings as well as a high degree of flexibility. This allows us to quickly manufacture, test and efficiently optimise different variants.”

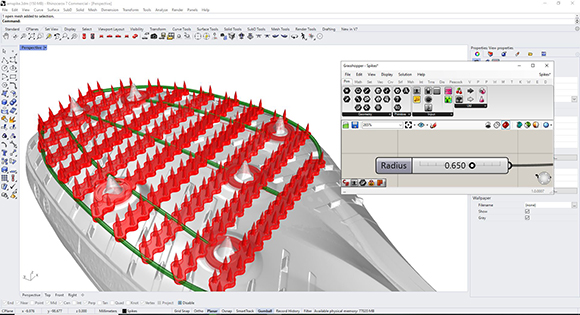

The geometry of the spike plates is developed using software and automatically aligned with the topography of the individual shoes, which is recorded by a 3D scanner. The spike plates are then additively manufactured using a Laser Powder Bed Fusion (PBF-LB) process.

Various alloys and geometrics are currently being tested and refined. Once the basic parameters have been determined, software is used to automatically adapt the design of the spike plate to any type of shoe, any shoe size, and any number of attachment points on the sole of the shoe. It will also be possible to produce special spike plates for the individual requirements of athletes or even for different weather and ice conditions.

“We tested the spike plates in the World Cup and received a lot of positive feedback from the athletes,” added bobsleigh head coach René Spies. “Nevertheless, a few tweaks are still necessary here and there, but we expect to have the perfect shoes to compete in by the 2026 Olympic Winter Games at the latest.”

Download Metal AM magazine