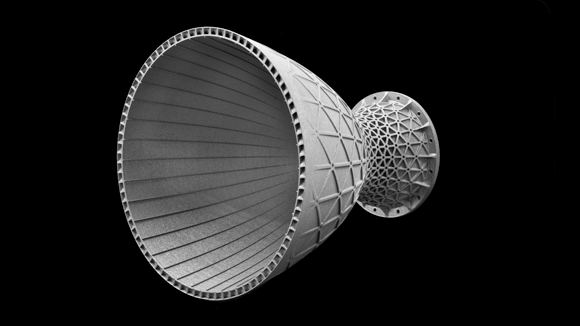

Betatype & nTopology develop optimised rocket nozzle part by metal AM

July 19, 2019

Betatype, London, UK, and nTopology, New York City, USA, recently partnered to develop and produce a functionally optimised rocket nozzle part by metal Additive Manufacturing. The project is said to have resulted in a notable reduction in build time on the AM system, from twenty-five to eighteen hours.

nTopology designed the base mechanical structure of the part using its nTop Platform software to convert a 3D model of the nozzle part into an implicit model. The team then used nTopology’s topology optimisation and simulation tools to optimise the design of the part for the Laser Powder Bed Fusion (L-PBF) process, using Betatype’s unique Engine and Process Control technology

The part was additively manufactured in titanium on a Renishaw RenAM250 system by Betatype. Designed to serve as a test part, it highlights how functionality can be improved through the application of intelligent design while still ensuring a part is fit for purpose, and that complexity and functionality does not necessarily come at the expense of productivity.

Sarat Babu, Betatype’s Founder and CEO, stated, “Betatype’s partnership with nTopology is an excellent demonstration of how we can work with talented designers to make Additive Manufacturing perform. The application clearly shows the benefits of combining the functional design and optimisation skills of our partner with process optimisation through our technology to achieve productivity levels that would not otherwise be possible with a standard metal L-PBF platform.”

Brad Rothenberg, Founder and CEO of nTopology, added, “For serial production in Additive Manufacturing to work, it must make business sense. Through the partnership between nTopology and Betatype, and our shared belief in solving engineering problems by linking design, simulation, and manufacturing processes directly, we are able to present a strong business case for Additive Manufacturing. We enable our customers to design and manufacture complex parts with speed, efficiency and reliability. We could not be happier with the results of this rocket nozzle case study and are looking forward to working on more joint projects.”