BCN3D optimises its Epsilon Series of AM machines

January 20, 2023

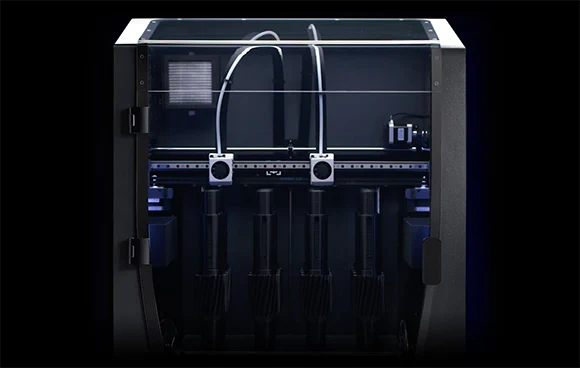

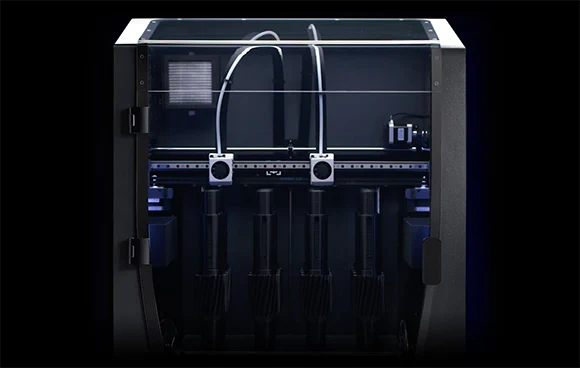

BCN3D Technologies, Barcelona, Spain, has announced a number of improvements to its Epsilon Series of AM machines. The range of machines use Fused Filament Fabrication (FFF), a form of Material Exrtrusion (MEX), and can process stainless steel through the company’s Metal Pack optional upgrade.

According to the company, a large part of the Epsilon’s series improved efficiency is said to be attributed to new electronics features, including the ventilation system, motor drivers and main board. Previously, the ventilation system introduced cold air inside the fans with extraction towards another grid. BCN3D found that this could potentially cause turbulence in the interior, resulting in occasional inefficiencies and resolved this by extracting hot air flow from the interior and lowering internal pressure to let the interior absorb air from the outside.

The Trinamic TMC2130 motor has been replaced with the TMC2226, which are said to be quieter whilst performing with greater efficiency and better engine torque. Whereas their predecessors required heatsinks to cool down, the TMC2226 only heat up slightly. The main board was also replaced with custom-made single board, as opposed to several commercial pieces.

One feature the company expects will be highly anticipated is local network access, an internal web server which allows users access via its local IP address.

Autocalibration XYZ is another new feature, reportedly reducing build time from forty minutes to six, a reduction of 85%. This calibration process is done by measuring multiple points to automatically adjust the build surface height and (XY) offset between both nozzles.

For machines equipped with an Independent Dual Extrusion System (IDEX), BCN3D had to take the XY alignment of the two toolheads into account. This is done through the use of a square located at the back of the build surface; the toolheads use this small opening to touch the sides with the hotends, calculate their positioning on both the left and right axes, and subsequently calibrate the right offsets between them. This XY alignment is said to ensure they are perfectly aligned and avoids any crossovers or shifting layers when additively manufacturing in dual mode.

All versions of the new generation of the Epsilon Series (W50, W27, W50 SC and W27 SC) are now available to purchase through BCN3D’s reseller network.