Authentise secures three grants in support of its Open Innovation initiatives for Additive Manufacturing

February 22, 2024

Authentise has announced it has been awarded three grants in support of its Open Innovation initiatives. Supported by Innovate UK, the US Department of Energy and Eureka, the projects look drive Additive Manufacturing applications and make the process more secure and efficient.

“These grants show that Authentise keeps pushing the boundaries of Additive Manufacturing to help accelerate the technology benefits of our customers: AM power users,” stated Erica Vlahinos, VP of Additive Manufacturing at Authentise. ”Together, we are delivering a more secure and efficient technology, ready to penetrate further into the heart of manufacturing as a whole.”

Simon McCaldin, VP Open Innovation at Authentise, added, “Authentise has always pursued a very intentional open innovation approach working with a myriad of partners around the world to address some of the industry’s most pressing challenges. We’re delighted to have been trusted by both our project and funding partners to provide the digital backbone of the solutions. We’re excited to share the progress of these and many other projects to come.”

The grants are listed as:

- METAMAT: Lattice structures are a key value driver for AM, but manufacturing challenges remain. Together with NS85, Teesside University, Lancaster University, and Holdson, Authentise aim to overcome these challenges and ensure highly functional metallic lattice parts at scale. Authentise’s role in the project is to develop a seamless integration between manufacturer, designer and customer. The project is part of the Resource efficiency for materials and manufacturing (REforMM) programme funded by Innovate UK (#10081046).

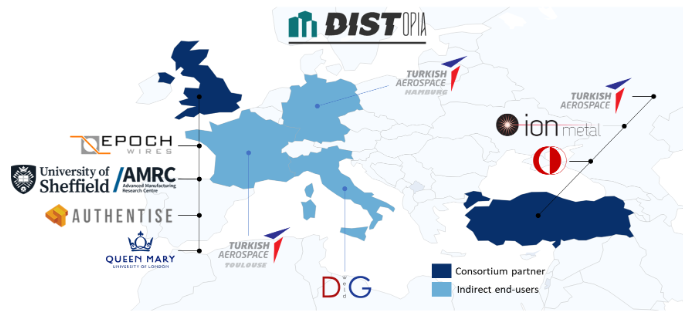

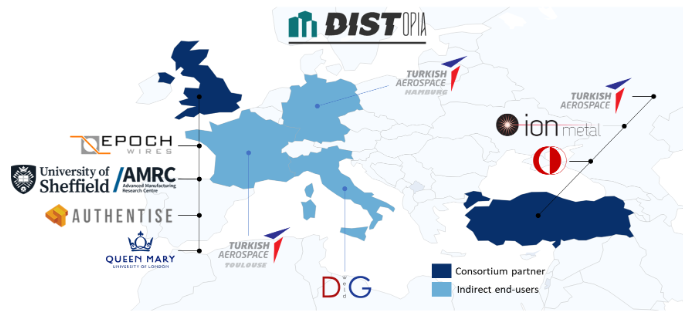

- DISTOPIA: Together with EPOCH, AMRC, Queen Mary University London, ION Metal, and Turkish Aerospace, Authentise aims to develop a seamless, ready-to-use plasma-based Directed Energy Deposition (DED) solution that addresses the pressing needs of the manufacturing, repair, and remanufacturing sectors, especially in aerospace. Authentise will use its expertise in data-driven workflow management and digital manufacturing methods with state-of-the-art material technology. Distopia is enabled by Eureka’s SMART advanced manufacturing cluster and funded by Innovate UK (#10086469).

- AM-Verify: Authentise has been chosen as one of ten projects selected for funding by the US Department of Energy through the Cybersecurity Manufacturing Innovation Institute (CyManII). The project aims to build a secure real-time measurement system specifically to detect if malicious third parties have infiltrated an AM system to adjust or introduce defects. Authentise, I3D MFG, and Addiguru will demonstrate multiple verification data streams, all integrated into the CyManII-developed Cyber-Physical Passport. The result not only looks to improve cyber security, but also aid AM manufacturers in their ability to improve manufacturing quality assurance, marking a significant leap towards safer and more reliable AM practices.

Download Metal AM magazine