Authentise and Solukon to integrate Solukon Digital Factory Tool into aMES

December 9, 2021

Authentise, Philadelphia, Pennsylvania, USA, and Solukon Maschinenbau GmbH, Augsburg, Germany, have announced that they will integrate the Solukon Digital Factory Tool into the advanced Manufacturing Execution System (aMES).

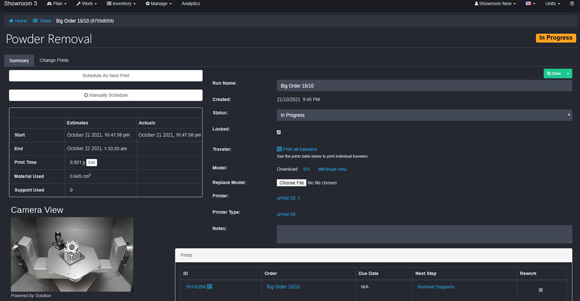

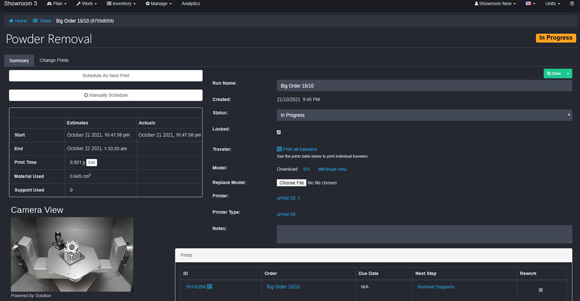

Solukon offers a full range of industrial powder removal systems for Additive Manufacturing and has recently added advanced analytics capabilities into its postprocessing systems through the Digital Factory Tool, a sensor and interface management solution. The tool is said to allow easy integration of automated powder removal into an overall digital AM process by providing continuous documentation and real-time monitoring.

“By partnering with Authentise, we are taking the next logical step after the introduction of the Solukon Digital Factory Tool,” stated Andreas Hartmann, CEO and CTO of Solukon. “Seamless data collection and interpretation throughout the entire production and post-process is the only way to achieve a true production line in additive manufacturing. Together with Authentise, we are closing a gap in data transparency and open the way for real Industry 4.0 projects.”

The integration of the Solukon powder removal environment will enable users to continue the powder to part genealogy using Authentise’s leading material traceability module. This will increase opportunities for improved post-process inspection recording and recycling of recovered materials. In addition, real-time alerts generated by the Solukon system inside aMES will help the user address any deviations during the process and improve powder recovery.

Since aMES already captures data from AM machines and manages the buildable geometry, the system passes this information on to Solukon automatically, saving the user from locating and uploading this information separately. The insight generated is appended to the existing aMES part report to ensure end-to-end traceability. In the future, both companies aim to integrate Solukon’s automatic toolpath creation into aMES to help users identify the optimum automated powder removal process for their specific application.

Andre Wegner, CEO of Authentise, commented, “This is the first time that Authentise has extended its ability to communicate beyond additive devices into post-processing equipment. The benefits are immediately obvious: higher labour and material efficiency, as well as better traceability for users.”

“The partnership is driving near immediate Return on Investment for our users,” he added. “The collaboration proves once again that customers can benefit from leaders in AM workflow joining to create tools that not only benefit the customer but make the all-important step to creating pathways to more sustainable industrial Additive Manufacturing.”