Authentise and Addiguru integrate in-process monitoring into AM workflow

September 9, 2020

Authentise, a developer of data-driven workflow tools for Additive Manufacturing founded in San Francisco, California, USA, with offices in London, UK; Kiev, Ukraine and Philadelphia, Pennsylvania, USA; and Addiguru, a provider of real-time monitoring solutions for AM, have collaborated to extend the Authentise Manufacturing Execution System (AMES) to include real-time process monitoring powered by Addiguru, Los Angeles, California, USA, based on computer vision and artificial intelligence (AI).

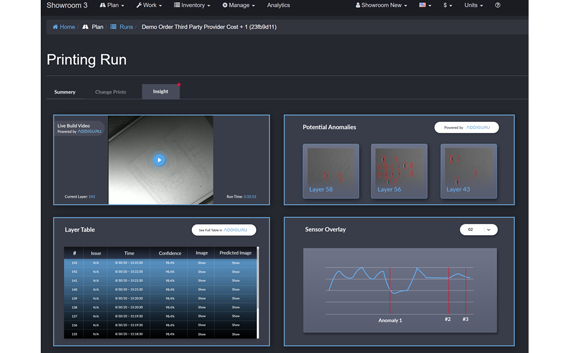

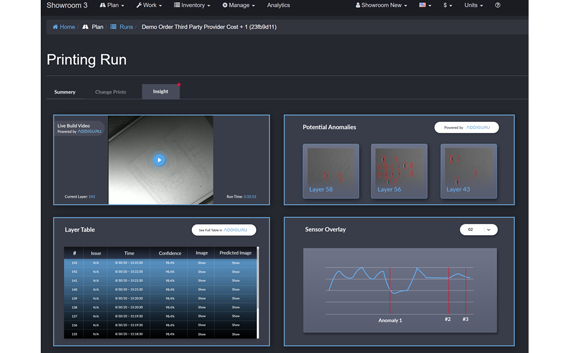

The companies explained that the integration of Authentise with Addiguru will provide a seamless experience for users who are seeking to gain practical use from their AM monitoring systems. In the integrated solution, alerts from Addiguru algorithms create real-time notifications within the Authentise web interface and app, display images highlighting potential issues, and visually spotlight the alert within the full workflow view.

The full data suite of images and findings is said to be automatically added to the real-time traceability alert and in a new analytics section for each machine and build. This includes the ability to overlay detected anomalies with sensor data taken from Authentise’s access to machine data. Each user can also use this data to create custom alerts, reports and dashboards.

“Existing in-process monitoring tools either require the user to have spent days setting up trial prints or to click through every image to detect potential flaws,” stated Shuchi Khurana, CEO of Addiguru. “The combination of our AI-driven insight and Authentise’s workflow tools enables the user to gain practical benefit in a system they love by having all data and notifications in one place. This initiative with Authentise also moves us closer to our goal of an open architecture framework.”

Andre Wegner, CEO of Authentise, commented, “The collaboration with Addiguru is a success because each party brings unique skills: Authentise provides coherent control of the digital thread and access to machine data, to which Addiguru can add visual inspection and intelligent analysis.”

“Our collaboration with Addiguru is testament to both Authentise’s openness and the continued inventiveness of the startup community,” Wegner continued. “While incumbent providers try to develop everything in-house, we work with the brightest minds to ensure that critical, cutting-edge solutions enter the market rapidly.”

“Addiguru joins a variety of partner modules in areas such as geometric search, mesh healing, or quoting. Their integration into our MES makes ground-breaking solutions accessible, affordable and seamless. We are proud to guarantee our clients that they will always have access to best-in-class solutions.”