Australian dental lab improves accuracy of dentures with metal Additive Manufacturing

April 13, 2018

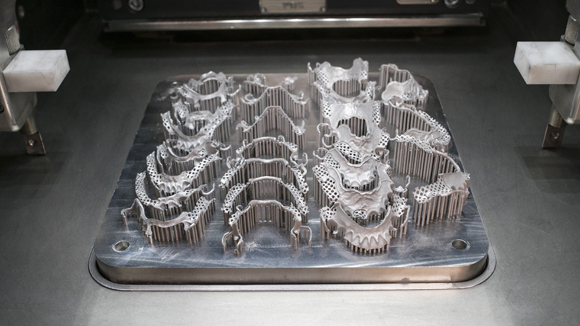

Additively manufactured removable partial dentures on the build plate (Courtesy Renishaw plc)

Proslab, a dental laboratory based in Canterbury, Victoria, Australia, states that it has fully digitalised the manufacture of its cobalt chrome removable partial dentures (RPDs) using metal Additive Manufacturing from the UK’s Renishaw plc. The company has now installed what is thought to be the first metal AM system for dental applications in Australia.

The dental lab was founded over thirty years ago, and fifteen years ago became the first Australian dental laboratory to use CAD/CAM processes for metal denture frames. Before working with Renishaw, the company had introduced a partially digital workflow, using 3D scanning and design tools, to design dentures.

Once designed in CAD, the dentures were printed in resin before being manufactured in cobalt chrome using conventional lost-wax casting. According to the company it was this traditional, uncontrolled process which reduced the accuracy of its parts, despite their careful design. “Achieving a high level of accuracy with lost-wax casting is difficult,” stated Damian Synefias, CEO of Proslab. “This means frameworks often need to be reworked after being sent to the dentist and fitted to a patient.”

As a result, Proslab sought to overcome issues with human error and accuracy by incorporating a Renishaw AM 400 metal Additive Manufacturing system into the production of its dentures. “To demonstrate the accuracy of the process, Renishaw manufactured sample parts at its Healthcare Centre of Excellence in Miskin, Cardiff, UK,” explained Alex Harris, Applications Engineer at Renishaw. “Our dental production facility runs daily, so there was extensive data to prove that AM was a viable if not ideal solution.”

The AM 400 machine enables the production of removable partial dentures directly from a CAD file, eliminating the additional casting step. Frameworks are built in 40 µm layers of CE marked cobalt chrome powder and built by laser powder bed fusion (PBF) using a high-powered ytterbium fibre laser.

To ensure a smooth transition from lost-wax casting to AM, Renishaw’s AM team conducted a week-long training course with Proslab’s staff and offered ongoing support from Renishaw Oceania, in Mulgrave, Victoria, Australia. “Training and support was our priority when purchasing the machine,” explained Synefias. “Throughout the process, Renishaw offered outstanding technical support and training to meet this requirement. We were confident in our investment as we trusted the product from the very beginning. This trust, combined with the exceptional support, meant that there was not one moment during the process where we felt uncomfortable.”

“Proslab is now able to produce the most accurate frameworks possible,” he continued. “Directly printing from a CAD file means we have reduced the number of in-house remakes due to error by 100%. If any error were to occur, we’d quickly be able to identify the source and amend it.”

Because of the improvement in accuracy that the AM 400 offers, Proslab can now ensure each framework fits the patient perfectly and has been able to reduce the overall manufacturing time for each partial denture. “By cutting out the casting step, we can now produce removable partial dentures in half the time,” continued Synefias.

“Proslab is the first Australian dental laboratory to incorporate additive manufacturing, and we now have access to the most up to date technology in the world. We have also improved turnaround times to a five-day cycle, improving the service to our clients.

[…] The project has been such a success that we plan to purchase another machine,” he concluded.