ASTRO America to streamline supplier qualification for aerospace Additive Manufacturing

December 4, 2023

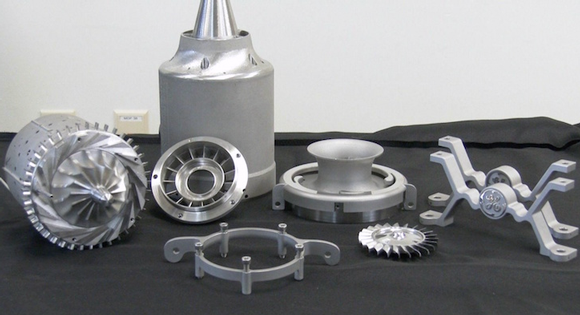

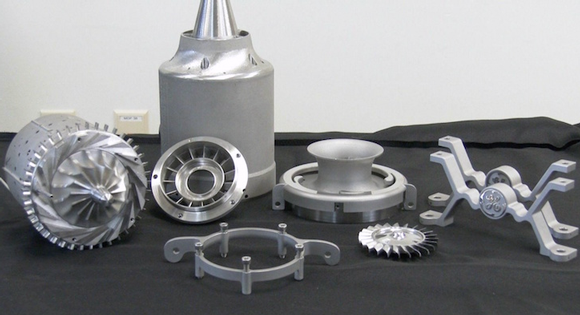

The Applied Science & Technology Research Organization of America (ASTRO America), located in Bethesda, Maryland, USA, has formed a new partnership with Pratt & Whitney, Honeywell, and GE. This partnership aims to simplify the process for small Additive Manufacturing vendors to become suppliers.

Currently, these aerospace companies each have unique processes for integrating new suppliers or machines into their supply chains. These processes validate that a new supplier or machine consistently demonstrates repeatability, reproducibility, predictability, safety, and production consistency. To streamline this process, ASTRO plans to collaborate with its partners to develop a plan and set requirements for a common Additive Manufacturing qualification template.

This detailed qualification template, using systems engineering methodology, that outlines the requirements necessary to meet OEM needs for Operational Qualification and Installation Qualifications. Furthermore, ASTRO will identify a specific material/machine combination to demonstrate the common qualification template. The organisation will then conduct an analytic analysis of this demonstration, the results of which will then be reviewed by a government advisory team, which includes AM officials from several federal agencies.

“Metal 3D printing is becoming an essential part of manufacturing jet engines. But it’s still very hard to get particular additive machines and materials approved for production. It’s costly and time-consuming for small aerospace suppliers. Ultimately, this can end up keeping good businesses and products out of the supply chain,” stated Neal Orringer, president of ASTRO America. “Now, for the first time, top-tier OEMs are coming together to address this problem and support broader adoption of AM and ASTRO is thrilled to lead this project and work with GE, Honeywell, Pratt & Whitney, and America Makes – and really make a difference.”

The qualification of Additive Manufacturing machines and materials is a significant obstacle to their widespread adoption. Gathering the necessary data and models requires significant time and resource investments from small to medium businesses to produce statistically significant data. This process typically involves generating coupons under a controlled process, testing these coupons, and analysing the data obtained. It’s also worth noting that part suppliers often need to provide vastly different data to each Original Equipment Manufacturer (OEM), even if they use the same manufacturing process. ASTRO believes that the OEM supplier qualification process, the requirements of which are usually proprietary, could benefit from standardisation across different application sectors like engine, structural, and mechanical subsystems.

To address this issue, ASTRO received an award from OUSD(R&E) via America Makes. The aim is to identify common Installation Qualification (IQ) and Operational Qualification (OQ) requirements for in-service metal AM parts. These requirements are accepted by the design authorities of three engine OEMs as part of their individual qualification/certification efforts.

“We are excited to work with GE, Honeywell, and Pratt & Whitney to develop a set of common qualification requirements for AM suppliers that can lessen the burden on suppliers and pave the way towards greater adoption of AM technologies,” Bill Tredway, ASTRO’s Senior Manufacturing Fellow and Principal Investigator for the CAM-QT project, shared. “Small and medium size AM suppliers should be able to take advantage of a common qualification template. The ripple effect will benefit the entire defence manufacturing supply chain.”

Download Metal AM magazine