ASME and NIST update AM design language standard

June 10, 2022

The American Society of Mechanical Engineers (ASME) has published a new standard, Y14.46, based on research by the National Institute of Standards and Technology (NIST). The standard provides guidance on how to relay Additive Manufacturing specific considerations in design documents.

While traditional design language works well for many traditional manufacturing methods, it has not equipped engineers to produce clear and consistent design documents for Additive Manufacturing. This absence of standard methods of communication leaves room for information about additively manufactured designs to be lost in translation. This new standard is intended to help engineers communicate to manufacturers, product inspectors and others in various industries more effectively.

“The industry is in a digital transformation right now, moving away from physical 2D drawings, and Additive Manufacturing is one of the catalysts since it requires digital 3D models,” stated Fredric Constantino, an ASME project engineering adviser. “And if you’re working on one of those models, this standard will guide you in making it understandable to both 3D printers and other people.”

Paul Witherell, Mechanical Engineer, NIST, commented, “Additive Manufacturing has opened the door to a lot of unique design opportunities for engineers, but that freedom also creates challenges in communicating complex designs.”

The lack of a consensus on how to convey aspects of a product related to Additive Manufacturing’s distinct capabilities has muddled communication between different organisations and may have created a barrier to more widespread use of the technology.

ASME responded to this roadblock in 2014, forming a committee of several dozen engineers from industry, academia and the federal government. The group, co-led by Witherell through 2019, sought to produce a uniform approach for defining additively manufactured products.

“We weren’t looking for ad hoc solutions. We were looking for solutions that could be standardised and implemented by the community to address these challenges with communication,” Witherell added. “We already know we can make good parts with Additive Manufacturing. Now the goal is to make lots of parts with Additive Manufacturing, and this is a necessary step.”

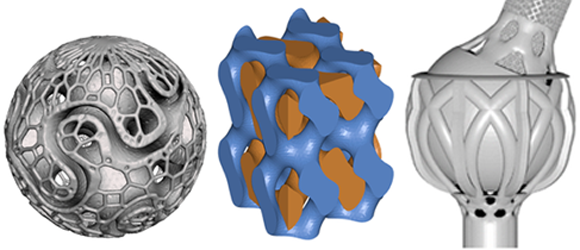

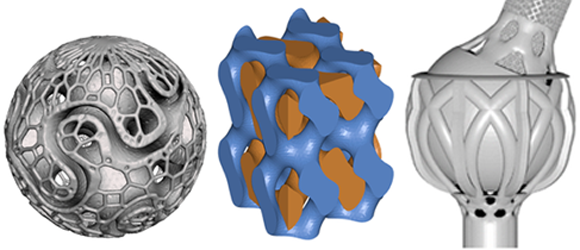

With the new guidance, the group introduces concepts to address not only the nuances of Additive Manufacturing designs themselves, such as their potentially intricate internal geometry, but the particulars of the build process. Factors, including the orientation of a build and whether temporary structural supports are additively manufactured, can influence the strength, durability and other properties of the end product.

Since Additive Manufacturing machines need digital product information to be presented in a particular way, the guidance also includes a section on how to package 3D-model-based data so that it’s machine readable.

Designers are meant to reference the new standard along with several previously established standards, which cover basic design considerations that are relevant to a broad array of manufacturing methods.

If adopted by major players in manufacturing, the standard could improve communication for Additive Manufacturing, potentially making for a more sustainable and efficient manufacturing industry in the future. However, expanding the standard along the way will be key.

“Some of ASME’s other standards go ten years, twenty years without revision, but Additive Manufacturing is advancing so rapidly. We aim to keep pace by adding to this standard as time goes on,” Constantino said. “We expect it to evolve quickly.”

More information on the standard is available via the ASME’s Additive Manufacturing Collection and NIST’s Measurement Science for Additive Manufacturing Program.