AMUG announces 2021 scholarship recipients

March 31, 2021

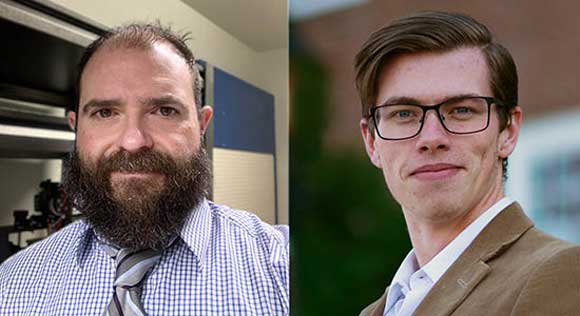

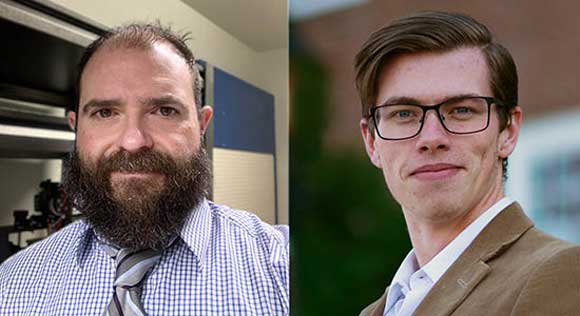

The Additive Manufacturing Users Group (AMUG), Milwaukee, Wisconsin, USA, has announced the recipients of its 2021 scholarships: John Sorvillo, Director for Westwood Prep Academy at New Beginnings, Youngstown, Ohio, USA, has been awarded the Randy Stevens Scholarship; Sean Dobson, who is pursuing a PhD in Material Science at the University of Cincinnati, Ohio, has been awarded the Guy E. Bourdeau Scholarship.

As scholarship recipients, Sorvillo and Dobson will attend the AMUG Conference, which takes place in Orlando, Florida, from May 2–6, where they will engage with Additive Manufacturing users. They will also present their work on May 4.

The annual scholarships honour and recognise students and teachers that demonstrate a passion for AM. The 2021 recipients demonstrate the passion in two ways: a dedication to advancing the technology and a commitment to advancing individuals through the technology.

Brett Charlton, chair of the AMUG Scholarship Committee, stated, “Educators are using AM to expand minds and stretch the boundaries of education. Students are tackling significant issues and expanding the applications of AM in the world. The applications were numerous, amazing, and inspiring. The committee had quite a challenge in making its selections, but it determined that John Sorvillo and Sean Dobson epitomised what the scholarships represent.”

Sorvillo is a licensed elementary school teacher who has been in educational administration for almost a decade. At the Westwood Preparatory Academy, the students are in residential care, most under court custody with no familial provisions. As a Director at the academy, Sorvillo builds programmes, teaches, and counsels with the goal of inspiring hope through education. He commented, “We try to leverage that education into their therapy, bringing us back to inspiring hope in them. We set them up to succeed in our classrooms. The more they achieve, the more they believe in themselves.”

Initially, the academy had one AM machine, but it struggled to incorporate it into instructional lessons. With Sorvillo’s efforts, it now has four AM machines that function as conduits for experiencing life skills, such as teamwork; acquiring technical skills, such as CAD design; and gaining ‘soft skills’ needed to function in society. Sorvillo added, “As amazing as the printers are, it’s the design and collaboration workstations that really make the difference. Our 3D printing programme has played a huge role in creating inspiration. We’re able to show at-risk students a whole new way of learning.”

“This technology has opened avenues of teaching that we never imagined. We are able to positively impact many facets of our student’s lives,” he continued. “3D printing has given us the ability to make our kids a positive force in our community.”

Sorvillo has extended classroom education through partnerships, collaborations, and grants where the students’ actions benefit others and themselves. Charlton added*,* “John’s outreach programs, which use Additive Manufacturing to make this world a better place through building people, is what allowed his application to rise to the top.”

As an undergraduate in mechanical engineering at the University of Louisville (U of L), Dobson’s introduction to AM occurred during an internship in Gulfstream Aerospace’s 3D Printing Laboratory. He commented, “I left the internship with a newfound desire for AM.” He also discovered an affinity for sharing that passion with others through training, tours, and collaborations. Dobson added, “There is an ingrained feeling of pride working in a field that can bring so many people together and engage the young and old in a STEM field.”

The interest in AM that he discovered during the internship led him to become an undergraduate research assistant in U of L’s Rapid Prototyping Center (RPC). There he found that metal Additive Manufacturing was the area in which he was most interested, and Dobson followed that path in working on RPC projects for organisations such as NASA and the U.S. Navy.

Charlton stated, “It is very inspiring to see what Sean Dobson has accomplished in AM. The technologies he has utilised and the process development advancements he has supported are advancing AM today.”

Dobson’s senior project—creating an affordable, modular desktop machine for fused filament fabrication (FFF), CNC milling, laser cutting, and injection moulding—spilled outside of the lab when he and two colleagues founded ModMan Technology. After receiving a Bachelor’s degree, Dobson earned a Master’s degree in Mechanical Engineering from U of L. During his studies, he continued his research for the U.S. Navy’s project as a graduate research assistant.

Currently working towards a PhD in Material Science at the University of Cincinnati (UC), Dobson also works for Vertex Manufacturing as an additive and material engineer. Greg Morris, CEO of Vertex Manufacturing and a pioneer in metal AM, said, “He has been a tremendous asset to Vertex Manufacturing. The passion that Sean exhibits for this field of work on a daily basis is inspiring, even for those of us that share the same passion.”

Regarding their presence at the AMUG Conference, Dobson noted, “AMUG is a place where the titans of our industry meet to discuss the current state of AM year after year; a place where individuals come to learn and share. This is why I want to attend AMUG; to learn from those who have experience far beyond my own, and to share what I have learned with those who may just be starting out.”

Sorvillo said, “I would love to see how this equipment operates in the larger picture of the entire industry and how we can incorporate that into lessons to better help our kids have a shot at success. I would like the opportunity to make contacts in this industry who can help us educate our students on what it takes to enter this field as a business owner.”