Ampower investigates potential cost savings offered by metal Binder Jetting and FDM

October 25, 2018

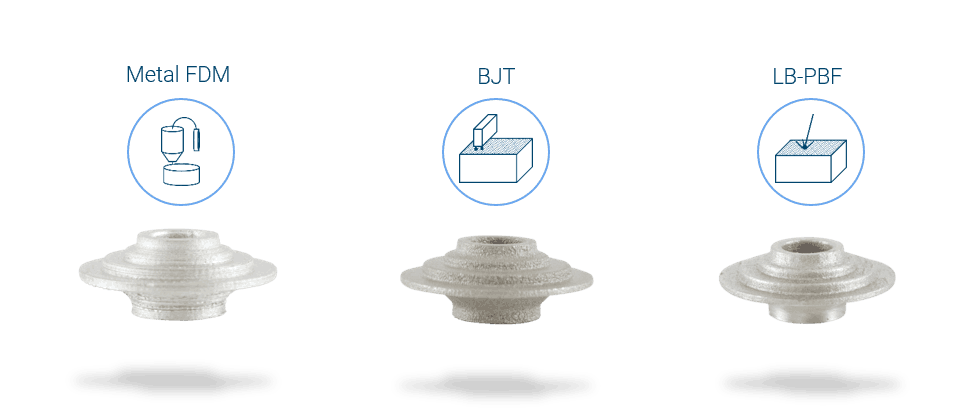

Ampower’s new report investigates and compares FDM, Binder Jetting and LB-PBF, as well as MIM (Courtesy Ampower)

Additive Manufacturing consultancy Ampower, Hamburg, Germany, recently published a study investigating and comparing metal Binder Jetting and Fused Deposition Modelling (FDM) with Laser Beam Powder Bed Fusion (LB-PBF) and Metal Injection Moulding (MIM).

In the study, titled ‘Additive Manufacturing with sinter-based technologies’, Ampower identified current cost reductions of approximately 40%, and future cost reductions of over 80% using the newer Binder Jetting and FDM methods of Additive Manufacturing. However, the report also highlighted some disadvantages of these newer technologies, such as limited material properties which could make them unsuitable for the production of highly-loaded components.

In addition, the complex sintering process involved in Binder Jetting or FDM was found to pose further challenges, such as component distortion. Matthias Schmidt-Lehr, co-author of the study and partner at Ampower, explained, “We expect that, especially in the automotive industry, binder technologies will prevail over high-volume cost-cutting as compared to LB-PBF.”

“Limitations on material properties and process risks can be offset by higher volumes and more complex process development,” he continued. “In demanding industries such as aerospace, industry will continue to rely on laser and electron beam processes. A short-term reorientation is not to be expected in these industries, especially as many OEMs have already set standards here and invested heavily.”

In addition to the principles of cost structure and material properties, the study also presents guidelines for the design of components for production using Binder Jetting. For the study, more than fifty samples from eight equipment manufacturers were evaluated and, in addition to tensile tests and metallographic density analyses, the surface roughness was measured and a CT analysis of the components carried out.