AML3D looks to revolutionise its WAM technology with Boron Nitride Nanotubes

December 2, 2021

AML3D Limited, Edinburgh, Australia, has announced a series of new proof-of-concept projects with Deakin University’s Institute for Frontier Materials (IFM) in Victoria, Australia, to explore the use of Boron Nitride Nanotubes (BNNTs) in an effort to revolutionise AML3D’s WAM® technology, also known as Wire Arc Additive Manufacturing (WAAM), a wire-based form of Directed Energy Deposition (DED).

Two feasibility studies, expected to commence immediately, will explore new techniques for incorporating BNNTs into aluminium suitable for use with AML3D’s WAM process, with a view to fast-track commercialisation.

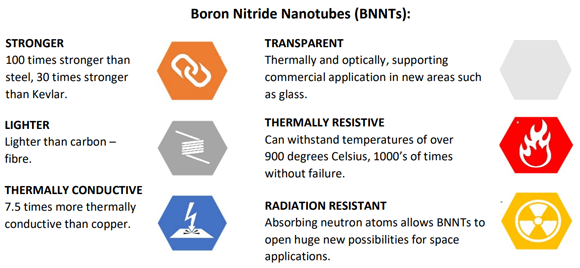

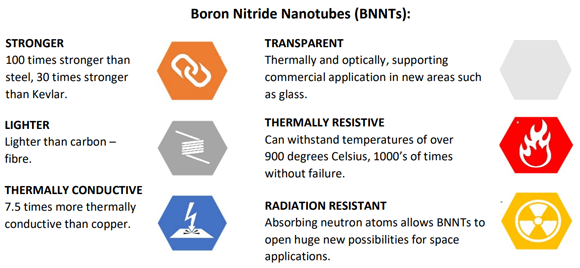

BNNTs are said to be the world’s strongest and most advanced fibre, with the capacity to greatly enhance the properties of WAM deposited alloys. The addition of BNNTs to aluminium and other metals can create much stronger, lighter, and more thermally and radiation-resistant alloys, greatly expanding the range of applications of AML3D’s patented WAM technology in key industries such as space, aerospace, marine, defence, and transport.

AML3D explains that these projects, which are funded by the company, are an opportunity to develop novel and transformative products with far-reaching implications for its WAM process and the metal AM industry. Encouraged by existing research within the BNNT space identifying the enhanced properties of the nanomaterial, AML3D has expressed its belief that the new projects are a step towards widespread commercial adoption of the material. With improving global production capacity and falling per-unit production costs, BNNTs are anticipated to revolutionise the advanced materials market, and AML3D is excited to spearhead the augmenting of this emerging technology with metal AM.

“The recent success of our current and ongoing high strength alloy developments for our patented WAM process, has identified a further significant commercial opportunity for AML3D by incorporating BNNT into our wire feedstock. I’m extremely encouraged by this new development and hence why we are commencing another two projects separately to our current program,” stated Andrew Sales, AML3D Managing Director. “Successful development of these particular alloys has the potential to provide the company with significant upside. The opportunities for products and components has application across all our target sectors and has the potential to add another game changing opportunity for us here at AML3D.”

Andrew Rau, Senior Commercial Manager at Deakin University, commented, “Deakin University is genuinely excited to be collaborating with AML3D to explore the feasibility of incorporating BNNTs with aluminium, utilising AML’s patented WAM technology. This research presents a unique opportunity to develop advanced materials with superior performance and develop a range of new applications for AML3D and their customers.”